Rune Thomsen is manager of broiler farming on the Williamsborg estate in Denmark.The company grows wheat, barley, rapeseed and peas on more than 1,000 hectares.They also have 110,000 broiler chickens.

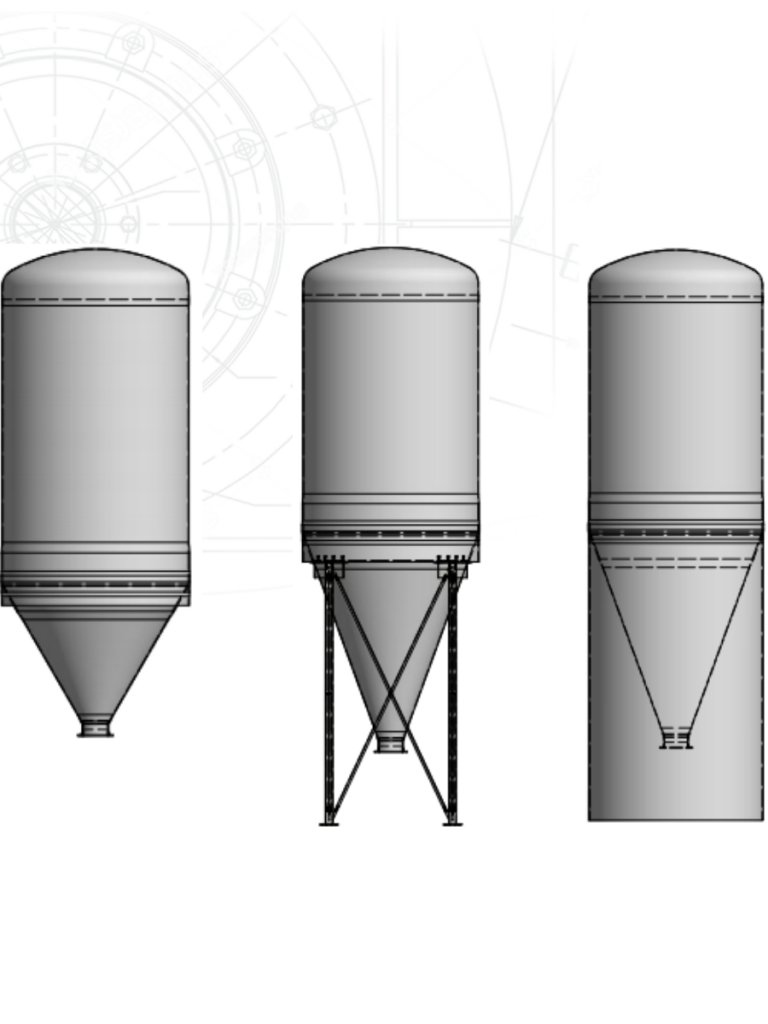

In 2015, an outdated pig farm was acquired that was in urgent need of renovation. The old stables were dismantled, leaving a blank canvas for the future of the farm. Over the next two years, 2015 and 2016, two impressive, identical sheds emerged from the dust and ruins. These new buildings were intended to house up to 55,000 broilers each, and they promised a new era for the company. Surrounding these shiny new sheds are a total of six impressive broiler feed silos from there nowned Polem brand. Four of these silos have a generous capacity of 60 cubic meters, while there maining two have a slightly more modest capacity of 13 cubic meters. These smaller silos are used as buffer storage for their own wheat which is mixed with the feed coming from the factory. Equipped with top and bottom sensors they are automatically filled from the bigger storage behind them. Due to current wheat prices this is not in use at the time, but it works really well and will be used again in the future.

The seamless construction of the silos eliminates potential weak points, safeguarding the stored feed against contaminants and maintaining optimal storage conditions.

The sheds on this typical Danish poultry farm, each with an area of approximately 3,000 square meters, followed the well-known pattern of broiler farming. Feeding lines, an ingenious combined system for ridge and longitudinal ventilation, inlet valves, six water lines and a generous amount of thick litter provided the optimal environment for the chicks.

_768_1024_s_c1.jpg)

_768_1024_s_c1.jpg)

_768_1024_s_c1.jpg)

_768_1024_s_c1.jpg)

_768_1024_s_c1.jpg)

Polem has the ISO 9001 version 2015 certificate.

Polem has the ISO 9001 version 2015 certificate. Polem has two DVS 1090 certificates related to the steel structures. One certificate is about the right material and construction calculations. The welding certificate concerns certified welding equipment and well-trained and certified welders. With this we meet the Eurpeese 1090 standard.

Polem has two DVS 1090 certificates related to the steel structures. One certificate is about the right material and construction calculations. The welding certificate concerns certified welding equipment and well-trained and certified welders. With this we meet the Eurpeese 1090 standard.  The German Institute for Structural Plastics (ISP) indicates that tanks and silos comply with the guidelines for fiberglass reinforced plastic products. Controled on calculations and production methods.

The German Institute for Structural Plastics (ISP) indicates that tanks and silos comply with the guidelines for fiberglass reinforced plastic products. Controled on calculations and production methods.  The TÜV certificate indicates that our tanks are approved to be used in a water protection area and guarantees that there will be no leakage to the bottom.

The TÜV certificate indicates that our tanks are approved to be used in a water protection area and guarantees that there will be no leakage to the bottom.

_768_1024_s_c1.jpg)

_768_1024_s_c1.jpg)

_768_1024_s_c1.JPG)

_768_1024_s_c1.JPG)