Innovation in industrial storage: how composite silos and tanks transform your business process

At the heart of every efficient production facility lies a crucial but often underestimated component: the storage solution. While advanced machines and technology typically get all the attention, it's the high-performance composite silos and tanks that act as silent forces ensuring the continuity of your business processes.The hidden foundation of industrial successWe understand that our storage systems are usually not the first eye-catcher in your facility. Positioned on the outside, between buildings or on the roof, they nevertheless form the foundation of your production chain – the reliable guardians of your valuable raw materials.The true value of premium storage solutions often only becomes visible when suboptimal systems fail. Leaks, product loss, or contamination can paralyze your entire production line and lead to significant financial damage and loss of reputation.High-quality composite silos: more than just storageA composite silo or tank functions as a strategic business system that:Guarantees consistent product quality by protecting against external influencesIncreases process efficiency with reliable and predictable material flowPromotes operational continuity through minimal maintenance requirementsExceeds safety standards for both products and personnelSuperior product flow: the distinguishing advantageConversations with industrial customers reveal that the most valued characteristic of our storage systems is the unparalleled flow reliability. For powders, granulates, and liquids alike: the product must exit the silo in the same condition as it entered, exactly when your production process requires it.Composite technology: the revolution in industrial storage systemsWhile conventional materials such as steel and concrete are still being used, advanced composite technology has brought about a revolution in the industrial storage world. The unique material properties make composite ideal for modern production companies that prioritize sustainability and maintenance efficiency:Seamless construction and mirror-smooth walls: optimal material flow without contamination risksComplete corrosion resistance: no degradation, even with chemically aggressive substancesSuperior thermal insulation: effective protection against temperature fluctuationsOptimal strength-to-weight ratio: easier installation without compromising durabilityStrategic investment with proven ROIA high-quality storage system represents a strategic investment in your business continuity and product quality. With an initial investment comparable to alternative solutions, a Total Cost of Ownership analysis shows the convincing long-term advantage:✅ Minimal lifecycle maintenance costs✅ Significantly longer operational lifespan✅ Reduced production loss through superior flow characteristics✅ Increased returns due to consistent product qualityProven applications in various sectorsOur composite silos and tanks prove their value daily in diverse industries. At FrieslandCampina in Lochem, a 600 m³ tank ensures effective wastewater management, while the Waalkens brothers rely on our tanks for the reliable storage of liquid fertilizer.In the food industry, our silos ensure safe storage of ingredients such as sugar, salt, and starch, while soy producers rely on our tanks for specific processes in their soy sauce production.It's not a silo or tank. It's a PolemIn an industrial environment where process reliability is essential, we offer the certainty of premium storage systems. Not just a silo or tank, but an integrated solution that supports your company in delivering consistent quality – day after day.Discover how our composite silos and tanks can transform your specific storage challenges into a strategic advantage. Contact our industrial market specialists for personalized advice.Every grain, every drop. Quality in, quality out.

The roof of a silo: often overlooked, always essential

At Polem, everything revolves around the right flow. It starts with a strong foundation, but is equally determined by the top: the roof. It's one of the components we include in every design by default – and often adapt to the specific application. Where others see the roof as just a lid, we see it as an opportunity to eliminate risks and improve performance.That's why every Polem silo comes standard with a domed roof design. Not just for aesthetics, but because it's better in every respect. For safety. For durability. And for hygiene. Polem's pragmatic, confident approach ensures we deliver quality you can rely on.Why the roof mattersThe roof of a silo endures severe conditions:Overpressure during filling - Pressure can rapidly increase during pneumatic fillingUnderpressure during sudden product movement - When product collapses in the silo, it creates a suction force that strains the roofWeather influences such as wind, rain, and UV - Years of exposure to the elements places high demands on durabilityMechanical load from components - The roof must not only support itself but also the additional weight of equipment and installationsA poorly designed roof therefore poses risks. Think of deformation, lekkage, condensation, or even danger during explosions. Yet in many designs, it doesn't receive the attention it deserves. At Polem, we make the difference by giving it priority.Why Polem chooses a domed roofA domed roof – also known as a Klöpper design – distributes forces evenly across the entire surface. This makes it resistant to higher pressure differentials. Polem silos can standard withstand a P-red of 1.0 bar. For comparison: metal silos often top out at 0.5 bar or less.What does this mean for your business processes?Better explosion safety - For dust explosion hazardous products, the roof offers more resistanceSmaller and fewer explosion panels needed - Instead of using large areas in the silo wall, smaller panels in the roof will sufficeHigher capacity utilization - Because no explosion panels are needed in the silo wall, you can fill the silo to a higher levelSmarter with space and integrationOur roofs are not only stronger but also more intelligently integrated with all necessary components:Flanges for filling systems, filters, manholes, and measuring equipment are seamlessly laminated – eliminating additional risk of leakage or thermal bridges. This prevents condensation and product deterioration.Composite flanges instead of metal - Unlike competitors, we use fully composite flanges, which eliminates thermal bridges and guarantees better adhesion.Explosion panels are placed entirely on the roof. No flanges in the silo wall. This prevents stagnant product and increases hygiene, which is essential for food and pharmaceutical applications.Central filling connection - For even product distribution and to prevent tilting, we position the filling connection in the center of the roof.Benefits at a glance✅ Higher safety through better pressure resistance ✅ Less explosion surface area needed ✅ Better hygiene through smooth roof surface ✅ No thermal bridges or weak spots ✅ Optimal integration of all components ✅ More room for customized solutions ✅ Less maintenance due to durable construction ✅ Better utilization of your investmentThe difference between a silo and a Polem? It's in the roofAt Polem, we design each component as if it were crucial. Because it is. Since 1972, we've built a strong reputation in the Netherlands and beyond. We've seen cases where poorly placed filling connections led to tilting. Filters that clogged due to condensation from a poorly insulated roof. Explosion panels that didn't function properly due to obstructions in the environment.That's why we pay extra attention to the upper part of the silo. Because that's where safety begins.You build silos from bottom to top. But the top makes the differencePrecisely because we focus on the essentials, we know where Polem makes the difference. Our approach is pragmatic, challenging, and confident. We know that the roof design of a silo is not a side issue but a crucial factor for the safety, efficiency, and lifespan of your investment.Would you like to know what a good roof design can do for your specific situation? Or would you like an analysis of your current installation to assess whether it is safe and optimally designed? Our market specialists are happy to look at solutions that fit your business processes.It's not just storage. It's Polem. And the difference starts at the top.

The hopper makes the difference: why hopper design in silos is crucial

At first glance, a silo seems like a simple storage facility. But at Polem, we know that the hopper design forms the heart of an efficient and functional system. With over 50 years of experience, we have learned that the details in this design make the difference between a standard silo and a premium storage solution.More than just an exit pointThe hopper is much more than a simple discharge opening. It is an essential component that directly affects:The discharge quality of your productThe ability to completely empty the siloThe hygiene inside the siloThe lifespan of your investmentAt Polem, we design hoppers that perfectly match your specific application.Hopper angles for every applicationEach product behaves differently in a silo. That's why Polem offers hopper angles that optimize flow:Each product behaves differently in a silo. That's why Polem offers hopper angles that optimize flow:40° hopper angle: Ideal for food and feed applications such as sugar, salt, or starch. This angle ensures mass flow ('first in, first out'), essential for perishable products.60° hopper angle: Suitable for abrasive bulk goods such as fertilizer, cement, or lime. Core flow reduces friction and wear on the walls.Special angles (e.g., 30°): For unique products, we design custom angles tailored to your situation.The Polem difference: rounded transitionsA distinguishing feature of our silos is the smooth transition from hopper to cylinder. Unlike the sharp angles of metal silos, this offers:Better product flow: No build-up in corners, which improves hygiene - crucial for food and animal feed.Lower material stress: Less stress on the laminate allows for more efficient, stronger construction.Mass flow versus core flowWhen extracting bulk goods from silos, two main flow patterns emerge:Mass flow: The product moves as a whole through the silo, with the material that enters the silo first also exiting first (First in, first out). This is ideal for perishable products and prevents material buildup.Core flow: Here, a funnel-shaped channel forms in the middle while product along the walls remains stationary. This reduces wear but can lead to product aging and clumping in stationary zones.Solutions for difficult flowing products For products with poor flow properties, such as rice husk or bran, we combine:A hopper with the right angleA suitable vibrating bottomPossibly a deflector This integrated approach guarantees efficient flow, even with challenging materials.Prevention of segregationWith mixed products, such as animal feed, segregation is a risk. A well-designed hopper with mass flow keeps the composition consistent, which ensures product quality.Centric filling and emptyingFor optimal performance and safety, it is crucial that silos are always filled and emptied centrally. Decentralized filling or emptying can lead to slanting of the product, causing large, unevenly distributed forces on the silo and potentially creating dangerous situations.Customization for your situationNo two applications are the same. Our market specialists are happy to discuss with you to develop the ideal hopper solution, based on your product and processes.Investing in qualityA good hopper design is more than functionality – it's an investment in:Higher product quality through better flow and hygieneLower maintenance costs through reduced wearLess downtime due to reliabilityA longer life of your siloPolem expert checkFor existing silos, Polem offers the Expert Check. During this periodic inspection, our expert technicians check, among other things, the condition of the hopper and advise on any adjustments or maintenance. This helps you to ensure the optimal operation of your silo and extend its lifespan.Optimise your processesWould you like to know how the right hopper design can improve your production? Contact our market specialists. They will share their expertise and find the best solution for your situation.Every grain, every drop. Quality in, quality out.

Precision storage in modern agriculture

The challenge: why storage is essentialIn today's agricultural sector, we at Polem understand that efficient storage is not a luxury but a necessity. Conversations with our agricultural customers reveal that the quality of storage systems directly impacts their business results. Moisture, product flow, and durability are challenges that many agricultural entrepreneurs face daily.What agricultural customers tell usIn our fifty years of experience developing storage solutions for the agricultural sector, we've learned a great deal from our customers. The problems they experienced with traditional steel silos – such as product clumping due to moisture and material remaining in corners and seams – have helped us better understand what's needed in the field.Experiences from poultry farmers: "Always perfect feed and no separation"Udo Baumeister and Stephan Werthmann, owners of Landwirt Baumeister in Breckerfeld, Germany, share their experience with our flat-bottom silos: "The flat-bottom silos are ideal; no separation and the feed always flows consistently.""We initially wondered if a flat-bottom silo would really make such a difference, but now we wouldn't want to be without it," says Baumeister. "When we heard about this silo from a colleague ten years ago, we already had several funnel silos from Polem. But I wasn't familiar with the flat-bottom. After positive reports from other poultry farmers and our feed supplier, we decided to take the plunge."The results proved convincing: "In the barn with the flat-bottom silo, we see higher laying percentages and better feed conversion compared to the two other barns with funnel silos. Our laying percentages are stable, the hens remain productive longer, and feed conversion has improved. We saw such a clear difference that we decided to replace our funnel silos with flat-bottom silos.""Very satisfied! No problems and easy to clean"Another experience comes from Rune Thomsen, manager of the Williamsborg estate in Denmark, a business with 110,000 broilers and more than 1,000 hectares of agricultural land where wheat, barley, rapeseed, and peas are grown."When we took over an outdated pig farm in 2015, we faced an enormous challenge," says Thomsen. "The old barns needed replacement, and we wanted to build a modern poultry farm with the best facilities. We chose Polem feed silos, and now – years later – we can say that we're still very satisfied with them."The Williamsborg estate uses six Polem silos: four 60 m³ and two 13 m³ for buffer storage. Thomsen particularly appreciates the hygienic aspects: "A major advantage is that the silos are easy to clean. We noticed this, for example, during a salmonella outbreak, when the cleaning process went smoothly."How different silo solutions address specific challenges1. Flat-bottom silos and quality preservationFor poultry farmers like Baumeister and Werthmann, the benefits of flat-bottom silos are concretely measurable:Continuous feed flow without interruptionsPrevention of separation of feed componentsFirst-in, first-out principle ensures that the oldest feed is used firstThe Air-Control system also ensures optimal temperature in the silo, preventing mold formation and feed quality loss. "This means less waste and stable nutritional value, regardless of weather conditions," says Baumeister.2. Hygiene and cleanabilityIn poultry farming, hygiene is a critical factor. Thomsen emphasizes: "The seamless construction prevents weak spots and keeps the feed in perfect condition. The silos are easy to clean, which proved crucial during a salmonella outbreak."This experience illustrates an important advantage of composite silos: due to the smooth surface and seamless construction, they are easy to clean and disinfect, reducing the risk of cross-contamination.3. Durability and ease of maintenanceThomsen appreciates the long-term benefits: "They are designed to last for years and remain in top condition, making our investment profitable in the long run. The combination of high-quality materials and thoughtful design ensures that we have experienced no problems with the storage or flow of the feed."Other customers also appreciate our composite construction primarily for:Absence of corrosion problems, even with aggressive fertilizersLong lifespan without visible degradation from UV radiationConsistent performance regardless of seasonal changesBaumeister confirms this: "The silos require minimal maintenance and ensure a constant feed quality, which is essential for the health and performance of our chickens."Automation and efficiencyModern agriculture demands efficient systems. Thomsen appreciates the advanced features: "The silos are equipped with automatic filling systems and sensors, allowing optimal management of our own grain buffer storage."Baumeister and Werthmann add: "Thanks to the right-angle transfer, the feed goes directly into the barn, without extra transfer points or sensors that could malfunction."These technical solutions directly contribute to operational efficiency:Fewer moving parts means fewer malfunctionsDirect transfer to the barn increases reliabilitySimple but effective systems reduce maintenance requirementsApplications for liquid product storageWith the brothers Hein and Lenus Waalkens, we've seen how the transition to composite tanks has led to what they describe as "reliable and solid storage of fertilizers." Their concrete experience aligns with what we hear from many agricultural customers.For liquid products, the choice of the right agitator proves essential. Our customers often start with standard 3 kW systems but sometimes switch to 4 kW HD agitators with increased service factor for more intensive use.The importance of maintenance and inspectionWhat we learn from our customers is the importance of regular maintenance. That's why we offer the Expert Check, where we work with customers to examine:The general condition of silos via an periodic inspectionEarly detection of potential problems to prevent costly damageAdvice on optimal use for specific applicationsWhy investing in quality storage pays offBased on customer feedback, we see that investments in high-quality storage systems pay off through:Reduced product lossesImproved product qualityLower maintenance costs in the long termFewer operational disruptionsAs Baumeister summarizes: "The flat-bottom silos from Polem have proven to be of tremendous value to our business. Our hens perform better, the feed is optimally utilized, and maintenance is minimal. It's an investment that more than pays for itself."Thomsen agrees: "The Polem silos offer our business not only convenience and reliability but also peace of mind. They contribute to efficient feed storage and an optimal living environment for our broilers."For each agricultural business, the specific benefits differ depending on what is stored and under what conditions. But the feedback we receive consistently confirms: the quality of storage directly influences the quality of the end product.For more information please check our website or contact us.

.png)

Sustainability as a foundation: Polem's long-term vision

Since 1972, Polem has been developing storage solutions built for the future. A future in which material use, energy efficiency, and product protection are becoming increasingly important. In this blog, we explore how sustainability is woven into every aspect of our products and approach.The benefits of composite for sustainable storageThe choice of composite as a base material offers numerous sustainability advantages that contribute to a lower environmental impact in the long term:Extended lifespan: Composite silos and tanks have a significantly longer service life than conventional alternatives, reducing the frequency of replacement.Natural corrosion resistance: Unlike metal materials, composite is naturally resistant to corrosion, preventing leakage and material deterioration.Low maintenance: The smooth interior wall minimizes product adhesion, resulting in easier cleaning with less water and cleaning agents.Thermal insulation: The insulating properties of composite help limit temperature fluctuations. This is not only beneficial for product quality but also reduces energy consumption in heated storage.Efficiency and product qualityTruly sustainable solutions contribute to reducing waste throughout the entire chain:Less product loss: The seamless construction reduces risks of contamination and degradation of stored products.Reducing downtime: Optimal flow and less maintenance mean fewer operational interruptions.Preserving product integrity: Better protection against external influences keeps raw materials in specification longer, reducing waste.Preventive maintenance as a sustainability strategyRegular inspection and maintenance are essential for maximizing the lifespan of storage systems. Proactive maintenance ensures:Early identification of potential problems before they lead to greater damageOptimal performance throughout the entire lifecycleData-driven insights into wear patterns, helping with future improvementsInnovation for future-proof solutionsContinuous improvement is the key to more sustainable storage solutions. Recent developments show how innovation offers practical sustainability benefits:Optimized constructions: Smart design reduces material use without compromising on strength or functionality.Improved accessibility: Innovative designs make maintenance easier, extending operational lifespan.Integrated safety systems: Modern grounding systems combine safety with sustainability and easy maintenance.The role of material choice in circular economyWhen designing storage systems, the choice of sustainable materials is crucial. Composite offers specific advantages in this regard:Thermal efficiency: Superior insulation properties save energy throughout the entire lifecycle.Freedom of form: Optimal shapes for product flow are possible, minimizing energy consumption during transport and processing.Resistance to chemical influences: Longer lifespan in demanding environments where other materials degrade more quickly.Long-term vision on sustainabilityA holistic approach to sustainability requires attention to the entire product lifecycle. This includes:Design optimization: Creating products that are intrinsically more sustainableMaterial efficiency: Striving for minimal material use while maintaining functionalityProcess improvement: Continuously seeking ways to make manufacturing and installation processes more sustainableLifespan extension: Supporting preventive maintenance and timely upgradesConclusion: sustainability as an integral valueSustainability is not a standalone concept but an integral part of quality. By focusing on long-term performance, maintainability, and material properties, modern storage solutions contribute to a future in which raw materials are optimally protected, processes run more efficiently, and environmental impact is minimized.By continuing to innovate and learn from practical experiences, we can build storage systems together that not only meet today's requirements but are also ready for tomorrow's challenges.

Expert Check: Protection for your Polem silos and tanks

Every grain, every drop. Quality in, quality out. This philosophy drives everything we do at Polem, including our commitment to maintaining the exceptional performance of our silos and tanks throughout their entire lifecycle.The value of expert maintenanceSilos and tanks are critical infrastructure in many industries. When they function properly, your processes run smoothly. But like all industrial equipment, they benefit from regular professional inspection and maintenance. That's why we developed the Polem Expert Check, a comprehensive inspection service designed to protect your investment and ensure optimal performance of your Polem silos and tanks.What is the Expert Check?The Polem Expert Check is a thorough annual inspection performed by our specialized technicians. We assess every crucial aspect of your silo or tank, looking for signs of wear, damage, or potential problems before they affect your business processes.During the Expert Check:Our technicians perform a thorough visual inspection of both internal and external componentsThey measure wall thickness with specialized equipmentThey check hardness levels with a barcol hardness meterThey compare measurements with original production specificationsThey inspect ventilation systems and filtersThey assess vibrating bottoms and their operationThey document findings with detailed photosThey provide expert advice on maintenance and optimizationWhy your Polem silo needs regular inspectionRegular Expert Checks offer significant benefits:Operational safetyRegular inspection and maintenance reduces the chance of damage and disruptions to your business process. By identifying potential problems early, we help you avoid costly downtime and ensure continuity.Extended lifespanPreventive maintenance ensures long-term preservation of the value and functionality of your silo or tank. Small issues addressed in a timely manner prevent more serious and expensive problems later.Process optimizationOur specialists can provide advice on improving the performance of your silo or tank based on your specific products and processes, for the right flow every time.The Expert Check processWorking with us is simple:Our After Sales department sends you a cost estimate for the inspectionAfter your written approval, we schedule the inspectionOur technicians perform the comprehensive checkWe prepare a detailed inspection report with findings and recommendationsIf repairs or upgrades are needed, we offer a separate quoteMore than standardWhile the Expert Check focuses on inspection and assessment, our service team is also equipped to:Perform GRP material repairsReplace componentsUpgrade systemsOptimize performanceQuality from the inside outAt Polem, we believe that quality isn't just about the products we manufacture; it's about ensuring they continue to perform excellently throughout their entire lifespan.The Expert Check is part of our commitment to supporting your business processes, even long after installation. By combining our more than 50 years of experience with regular professional maintenance, we help ensure that your Polem silo or tank remains what it was designed to be: a premium solution for your storage needs.Contact our Service department today to schedule your Polem Expert Check and protect your investment for years to come.

Composite vs. steel, aluminum, PP, PE and plastic silos and tanks

At Polem, we have been using high-quality composite materials since 1972 to create storage products that are seamless, strong, and mirror-smooth. In this blog, we dive deeper into the differences between composite and other materials for silos and tanks.What is composite?Composite is essentially a compound material consisting of two or more components with different physical or chemical properties. When these components are combined, a new material emerges with properties superior to those of the individual constituents.For Polem's silos and tanks, we use glass fiber reinforced plastic (GFRP), a specific type of composite. GFRP consists of:A polymer matrix (often polyester or epoxy resin)Reinforcement through glass fibersThis results in a material that combines the flexibility and design freedom of plastic with the structural strength of glass fibers.Composite versus other materialsGFRP (Glass Fiber Reinforced Plastic)GFRP is a specific type of composite. The term 'composite' is broader and can include other reinforcement materials, such as carbon fibers or aramid. At Polem, we use GFRP because of its excellent combination of strength, durability, and cost-effectiveness.PolyesterPolyester is often the resin matrix used in GFRP. It is therefore a component of the composite, not the composite itself. It serves as a binder for the glass fibers and provides chemical resistance.PP (Polypropylene) and PE (Polyethylene)These are thermoplastic polymers used without reinforcement for various applications. They are more flexible than composite but lack the structural strength and durability provided by glass fiber reinforcement.Steel and aluminumTraditionally, silos and tanks are often made of steel or aluminum. Although these materials are strong, they have significant disadvantages compared to composite:They are more susceptible to corrosionThey have poorer thermal insulationThey require welds and joints that can weakenThey have a rougher surface leading to more product adhesionThe advantages of composite for silos and tanks1. Seamless constructionOur composite silos and tanks are manufactured in one piece, without seams or welds that can leak or weaken. This results in hygienic storage where no product can accumulate in crevices or corners.2. Exceptional strengthDespite their relatively light weight, our composite structures are exceptionally strong and can safely store large quantities of material, even under demanding conditions.3. Mirror-smooth finishThe interior of our silos and tanks is mirror-smooth, which ensures:Better product flowMinimal product adhesionEasier cleaningImproved hygiene4. Corrosion resistanceUnlike metal alternatives, composite is virtually immune to corrosion, which significantly extends lifespan and reduces maintenance costs.5. Thermal insulationComposite naturally has excellent insulating properties. The insulation value of a tank or silo with 50 mm PU foam is comparable to that of a metal tank insulated with 100 mm rock wool and aluminum plating.6. Low maintenanceDue to its durability and resistance to both mechanical and chemical influences, composite products require less maintenance than conventional alternatives.Practical exampleIn the food industry, hygiene is crucial. The seamless finish of composite silos prevents product buildup in corners and crevices, which can cause mold formation and bacterial growth. Additionally, the mirror-smooth interior wall is ideal for products that are difficult to flow, such as powders and granulates that stick to rough surfaces.A customer in the dairy industry noticed a significant improvement in product flow and a reduction in cleaning time after switching from steel silos to composite. Additionally, the thermal insulation proved to be much better, leading to less condensation and better product quality.In the industrial sector, where many chemicals are used, the corrosion resistance of composite proves its value. While steel tanks regularly need maintenance or replacement due to degradation, composite tanks remain in perfect condition for years.FinallyThe choice of the right material for your silos and tanks directly influences the quality of your processes and end products. Composite offers clear advantages over traditional materials such as steel, aluminum, and unreinforced plastics.Every grain, every drop. Quality in, quality out.

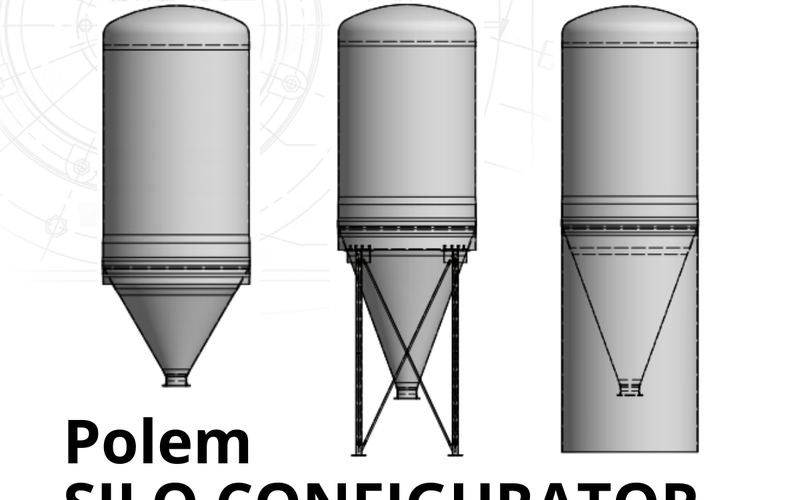

Configure your own Polem silo or tank: Discover the power of our configurator

First in. First out. Even in the preliminary process.The right storage solution starts with the right specifications. At Polem, we like simplicity, even in the preliminary process. With our online configurator, you can put together your ideal silo or tank step by step - precisely tailored to your needs, without unnecessary complexity.Your specifications, directly translatedWhether you are a supplier who wants to offer Polem quality to your customers, a system integrator looking for the perfect storage component for your installation, or an end user who wants the best solution directly - our configurator makes the process simple and transparent.Here's how it works:1. Specify your storage needs Start by entering the commodities you want to store, the capacity needed and any specific requirements you have. The configurator guides you through all relevant questions, without unnecessary technical complexity.2. Receive instant advice After entering your data, the configurator analyzes your input and provides instant advice on the most suitable storage solutions. The strength lies in its simplicity: all available options are clearly presented.3. Request a quote easily Satisfied with the specified silo or tank? With one click you can request a detailed quotation. After this, you will quickly receive a price quote so that you can proceed with your project.Benefits of the Polem configurator1. Precision without complexityOur configurator combines fifty years of craftsmanship with modern ease of use. You don't need to be a technical expert to determine the right specifications - the tool guides you through the process with clear questions and options.2. Save time in the preliminary processNo long waits for quotes or multiple calls to clarify specifications. The configurator gives you instant insight into what is possible, significantly shortening the preliminary process.3. Full insight into your optionsEach choice in the configurator immediately shows the impact it has on other aspects of your silo or tank. This gives you full insight into the options within your specific application.More than a digital toolThe Polem configurator is more than just a digital tool - it is an extension of our service. After using the configurator, our team of market specialists is ready to answer any questions or discuss specific details. For more complex applications or custom solutions beyond the scope of the configurator, the tool connects you directly to the right specialist within Polem. This is how we combine the best of both worlds: digital convenience with personal expertise.Get started todayThe configurator is accessible on our website. Discover for yourself how easy it can be to specify a high-quality Polem silo or tank. Configure your future silo or tank yourself. That's Service from Polem.Go to the configuratorPolem - seamless, strong and mirror-smooth. It's not a silo or tank. It's a Polem.

The right flow: why composite silos are preferable

Quality in, quality outEvery grain, every drop. In the world of storage, everything revolves around reliability and quality. Choosing the right type of silo or tank not only determines how well your raw materials are protected, but also directly affects your production process and end result.Since 1972, Polem has been providing storage solutions that are distinguished by three essential properties: seamless, strong and mirror-smooth. Our composite silos and tanks are designed to optimally protect your raw materials and improve your processes.Why composite is the better choiceWhen choosing a material for silos and tanks, each type has its advantages and disadvantages. Yet we confidently choose composite for these reasons:1. Seamless constructionUnlike metal silos, where the transition from cylinder to hopper often presents a problematic edge, a Polem silo offers a smooth, rounded transition. This has two main advantages:Product flows better along the wall, preventing accumulation of materialHygiene problems such as mold and bacterial growth are significantly reduced 2. Mirror-smooth inner wallUnlike metal silos, where the transition from cylinder to hopper often presents a problematic edge, a Polem silo offers a smooth, rounded transition. This has two main advantages:Less chance of bridge formation or “rat-holingEasier and more efficient cleaningBetter hygiene, especially important for food and feed applications3. Optimal thermal insulationComposite silos protect your raw materials from temperature fluctuations and thus from moisture problems. The insulation value of a Polem silo with 50 mm of PU foam is comparable to that of a metal silo insulated with 100 mm of rock wool. This means:Less condensationProtection against extreme temperaturesLower maintenance costs4. Corrosion resistanceUnlike steel or aluminum silos, composite silos are virtually immune to corrosion. This results in:Longer life of your investmentConsistent product quality without contaminationSignificantly lower long-term maintenance costsThe science behind the right flowAt Polem, we use advanced flow profiles. Depending on your product, we choose a funnel angle of 40° (mass flow) or 60° (core flow). This choice is crucial for the optimal processing of your raw materials. For example, for food products such as sugar, salt and starch, we recommend a 40° hopper that provides “First in, First out” (FiFo) flow - essential for perishable products. For abrasive raw materials such as fertilizer or cement, a 60° hopper is often optimal, minimizing wear and ensuring longer life.It's not a silo or tank. It's a Polem.Our focus on quality is reflected in every aspect of our products. From the carefully chosen materials to the thoughtful design of each component. The good name we've built up over 50 years is no accident - it's the result of consistent craftsmanship and attention to detail.Want to know what a Polem silo or tank can do for your production process? Get in touch with our market specialists. They will be happy to advise you on the optimal storage solution for your specific raw materials.Discover for yourself the difference the right flow can make: quality in, quality out.

New tank delivery for storage of food-grade calcium chloride

At Polem, we are always proud to contribute to the growth and success of our customers. Recently, we completed an important delivery for a customer in Veendam, where we supplied a tank for the storage of food-grade calcium chloride. This tank has an impressive capacity of 240 m³, ideal for safely storing this essential substance.What is food-grade calcium chloride? Calcium chloride is widely used across various industries, including the food industry. It is a versatile product used for food preservation, improving the texture of vegetables and fruits, and, in some cases, in food and beverage production processes. The "food-grade" variant ensures that the product meets the stringent requirements for use in the food sector.Why a 240 m³ storage tank? A tank with a capacity of 240 m³ is an excellent choice for companies that require larger quantities of food-grade calcium chloride. The tank not only provides sufficient storage capacity but is also designed to safely and efficiently store the product, maintaining its quality. Whether it is about product stability or practical application on the work floor, our tanks offer a reliable solution.Quality and service from Polem At Polem, we ensure that all our products meet the highest standards of safety and reliability. We understand that a reliable storage solution is crucial for the continuity of your business operations. Therefore, we not only provide tanks that meet the requirements but also offer customized solutions that perfectly match your specific needs.Why choose Polem? Our experience and expertise in designing and delivering storage tanks make us the ideal partner for businesses seeking quality storage solutions. We not only deliver the right products but also ensure careful installation and long-term support, all to ensure that your business processes run smoothly.Are you curious about what Polem can do for your business? Feel free to contact us for more information about our products and services!Polem - your reliable partner in storage tanks.

The right flow since 1972

Since 1972, Polem has been synonymous with the right flow in storage solutions. In our very early days, the focus was purely on the agricultural market. Farmers and agriculturists were looking for reliable storage for their crops, and we were there to provide just that. With passion for craftsmanship and a relentless drive for innovation, we have refined our expertise in composite silos and tanks step by step.What once began as a solution for the agricultural sector has grown over the years into a versatile offering for various markets. Our market specialists, by having direct conversations with clients and a constant eye on market developments, have helped us to broaden our portfolio. Today we supply our solutions not only to agriculture, but also to the food industry, the chemical sector and other industries where safe, efficient and sustainable storage of raw materials is crucial.What makes us so unique? It is the combination of more than 50 years of experience and our constant drive to innovate. At Polem, we seamlessly integrate engineering, manufacturing and consulting into our process. This means that our silos and tanks are not only technically advanced, but also perfectly tailored to our customers' specific needs. We are known for our “quality in, quality out” , a promise we keep every day by meeting the most stringent international standards and working closely with reliable system integrators.Our close cooperation with partners throughout the chain ensures that our storage solutions always integrate seamlessly into the overall system design. As a result, our expertise contributes directly to optimal production and operational continuity. With a passionate team of professionals, every day we build a future where all our customers, regardless of industry, can rely on uninterrupted flow.Discover how Polem's rich history and ongoing commitment to perfection contribute to a reliable future for your business processes. Or contact one of our market specialists directly.

Efficient activated carbon storage: discover the advantages of Polem composite silos

Activated carbon plays a crucial role in water treatment, air filtration and chemical processes. But its storage can be challenging. This adsorbent is susceptible to moisture, dust accumulation and even ignition. Inappropriate storage can lead to loss of quality and inefficiency, something you naturally want to avoid.The ideal storage solutionPolem offers the ideal solution with its advanced composite silos. Whereas traditional metal silos are prone to corrosion and condensation, our silos offer a safe, low-maintenance and extremely durable storage method. The unique properties of composite keep your materials in optimal condition, without the risks of rust or moisture problems. Our silos are not only strong and durable, but also flexible in design. They can be customized to meet your specific storage needs, including unloading facilities and aeration systems. In addition, the smooth-finished interior walls reduce material accumulation, making cleaning easier and minimizing downtime.Seamless, strong and mirror smoothA key advantage of our composite silos is their seamless construction. At Polem, we strive to make the transition from hopper to cylinder as smooth as possible. This ensures improved product flow where activated carbon flows better along the wall, without accumulation in kinks or corners. This is essential for a product like activated carbon, which can easily accumulate in uneven areas due to its powdery structure. The mirror-smooth inner walls of our silos prevent activated carbon from adhering to the walls, resulting in optimal product flow and minimal material loss. In addition, this reduces the risk of dust accumulation, which can lead to self-ignition in activated carbon.Optimal protection against moistureFor activated carbon storage, moisture control is crucial. Moisture significantly reduces the adsorption capacity of activated carbon, which limits its effectiveness in filtration processes. Polem composite silos offer superior protection against moisture by:Thermal insulation: Composite naturally has insulating properties that minimize temperature fluctuations and prevent condensation.Air drying systems: Our silos can be equipped with advanced air dryers that regulate the moisture content in the silo.Seamless construction: No cold bridges or gaps where moisture can penetrate or condense.Safety firstThe storage of activated carbon poses specific safety risks, including the potential for dust explosions. Therefore, our silos can be equipped with:Explosion panels: Strategically placed to safely vent pressure in the event of a dust explosion.Pressure release systems: Prevent overpressure in the silo during filling and unloading.Advanced grounding systems: Safely dissipate static electricity, a major ignition source in dust explosions.Polem's convex silo roofs offer improved resistance to under- and overpressure and can be designed for a P-red of 1.0 bar, essential for the safe storage of dust-explosive products such as activated carbon.Durability and cost efficiencyIn addition to their functional benefits, composite silos contribute to more sustainable operations. Less maintenance and longer service life result in lower operating costs and reduced environmental impact. This makes them not only a practical, but also a responsible investment. By increasing the shelf life of your activated carbon thanks to optimal storage conditions, you also reduce the consumption of this valuable material. The efficient emptying of our silos ensures that minimal product is left behind, contributing to higher cost efficiency.Broad applicability in various industriesActivated carbon is used in a variety of industries. From the filtration of drinking and wastewater to the purification of air and chemical processes -- reliable storage is essential for an efficient production process. Our silos are widely applicable and guarantee safe and efficient storage for various applications in water treatment, air filtration, food industry, pharmaceutical and environmental technology. With decades of experience in composite silo solutions, Polem is your reliable partner in storage. We provide customized solutions that make your storage more efficient, safe and sustainable.Expert Check for optimal performanceTo optimize the performance of your activated carbon storage system, we offer the Polem Expert Check. This service includes an annual inspection by our specialists, during which:The condition of the silo is checkedVenting systems are checkedWall thicknesses are measured to monitor wear and tearAny adjustments are advisedThese preventive measures ensure that your storage system remains in optimal condition and that the quality of your activated carbon is not compromised.Are you ready for optimal storage?Are you ready to optimize your storage processes? Contact us and discover how our composite silos can make the difference. Our market specialists will be happy to think with you about the best storage solution for your specific situation, so that you can benefit from all the advantages that Polem silos offer.Every grain, every drop. Quality in, quality out.