High-quality composite process tanks: sustainable solutions for your production

At the heart of modern production facilities, you'll find them: composite process tanks. These frp tanks may not always be visible to the naked eye, but they form the backbone of countless processes in the food, feed, and industrial sectors. Process tanks are specially designed for storing liquids during crucial production phases. At Polem, we understand better than anyone how vital the right process tank is for your business continuity and product quality.The power of seamless composite process tanksWhat distinguishes Polem tanks is our unique production method. Our seamless tanks are manufactured from a single piece, resulting in a completely seamless construction. This offers significant advantages for your industrial storage needs:Mirror-smooth inner walls: ensure optimal hygiene and minimal product accumulation in your storage tankStrong construction: durable process tanks that withstand intensive useCorrosion resistance: no degradation of your composite tank from aggressive substances or moistureMinimal maintenance: lower operational costs in the long term for your frp tanksFor fermentation processes, these properties of seamless composite tanks are invaluable. The seamless process tanks prevent unwanted bacteria from nesting in seams or crevices, which is crucial for food safety and product quality in the food industry.Custom process tanks for your specific production processEvery production line is unique and requires specific storage solutions. At Polem, we develop your process tank with attention to all the details that are important for your industrial process:Capacity up to 1,500 m³: for both small-scale and large-scale production in industrial environmentsVarious tank bottoms: choice of dished bottoms (klöpperboden), conical bottoms, or flat bottoms, depending on your processHeating systems for tanks: various heating options to maintain the right temperature in your process tankAgitators for tanks: top-entry or side-entry agitators for optimal mixing in your process tankFor fermentation tanks, for example, we can equip custom tanks with specific heating systems that guarantee the ideal temperature. At Polem we say: "you conceive it, we've already made it for your industry."The right flow for your production process with high-quality storage tanksWith composite process tanks, it's not just about storage, but especially about the flow of your product. If the product doesn't flow through your process correctly, this can lead to quality loss or production interruptions. Our engineers consider:Optimal inlet and outlet positions in tanks: for an even product flow in industrial environmentsAccessibility for cleaning tanks: strategically placed manholes and inspection hatches in your process tankIntegration with your existing systems: seamless connection of your frp tank to your production lineReliability as the foundation of your sustainable storage tankAt Polem, we don't build for the short term. Our frp tanks are designed to last at least 20 years, and in practice, these high-quality process tanks often last much longer. This suits companies in the food industry and feed industry that value continuity and sustainability.Investing in a Polem process tank means choosing:✅ Long service life of tanks: at least 20 years of high-quality performance from your composite tank✅ Reliability of storage tanks: minimal downtime due to technical problems with your industrial tanks✅ Process certainty: consistent production results through high-quality frp tanksYour partner for process tanks at every stageFrom engineering to installation and service of your composite tanks – Polem is ready to assist you. Our market specialists understand the specific challenges in your industry and think along with you about the best storage solution. After installation, we remain your partner with our expert check service, where we regularly inspect your process tanks for safety and optimal operation.Every grain, every drop. Quality in, quality out.As our slogan says: at Polem, everything revolves around the quality of composite tanks. We believe that a high-quality frp process tank leads to a high-quality end product. Through meticulous craftsmanship and years of experience, we can support your production process with corrosion-resistant storage tanks that meet the highest standards.Would you like to know more about our composite process tanks and how they can optimize your production process? Contact our market specialists for personal advice on industrial storage tanks.It's not a tank. It's a Polem.

Static electricity in silos: invisible, but never innocent

Static electricity poses a real explosion risk when filling and emptying silos with dry materials. During this process, electrostatic charges develop through friction. Just one spark is enough to cause a dust explosion. This applies to both metal and composite silos.In sectors such as food, chemicals, and feed – where flammable or explosion-sensitive materials are handled – this risk cannot be ignored.How Polem solves this problemAt Polem, safety is paramount. In collaboration with ISMA (Kontich, Belgium), we developed a certified grounding system, specifically for silos containing explosion-hazardous bulk materials.The advantages of the system:Reliable grounding - Effectively captures static charge and complies with applicable safety standards.Hygienic design - The stainless steel screw plug and open fork connection are easy to clean and prevent dirt accumulation. Important for food and feed environments.One-piece construction - Made of special stainless steel spring steel, without welded seams. This prevents breakage and extends service life.Freely hanging grounding - The grounding rods follow the flow pattern of the product in the silo, for consistent effectiveness.Simple maintenance - The system can be visually inspected without disassembly.Safe not only inside, but outside tooIn addition to the internal grounding rods, grounding of external metal components is also advised. This creates a complete solution without weak links.Why choose Polem?✅ More than 50 years of experience in composite silos and tanks✅ Leader in ATEX solutions for explosion-hazardous environments✅ Rapid implementation, minimal interruption✅ Complete support from advice to maintenanceReady for stricter requirementsOur grounding system helps you comply with current and future safety standards. This provides peace of mind during audits, inspections, and insurance assessments.Security starts at the foundationEliminating static electricity is not a detail, but an essential part of your process safety.Let our specialists analyze your situation and receive tailored advice. Within a few days, your silo will be protected – without significant downtime.Want to know more?Contact Polem or request a no-obligation consultation directly.Every grain. Every drop. Safely stored. It's not just a silo. It's a Polem.

Celebrating freedom. Ensuring quality.

On May 5, the Netherlands celebrates freedom. A valuable moment of reflection and looking ahead. At Polem, we reflect on this too. That's why our company is closed on Liberation Day.But even when we're not there, our knowledge and service continue to run online. Take the opportunity to explore our solutions - and discover why more and more companies are choosing Polem:✅ Seamless, strong and mirror-smooth silos and tanks - Thanks to composite construction suitable for the highest requirements in terms of hygiene, durability and safety.✅ The Polem Configurator - Easily put together your desired silo or tank yourself. You will immediately receive an indication of what is technically and practically possible.✅ Practical examples - Be inspired by reference projects in a variety of markets: from food and animal feed to chemicals and ice control.✅ Maintenance and service, for the long term - Our silos and tanks are known for their longevity. But processes change. Our service page tells you how we continue to contribute to continuity even after delivery.Find out what Polem can also do for you.From Tuesday, May 6, we will be at your service again in person.

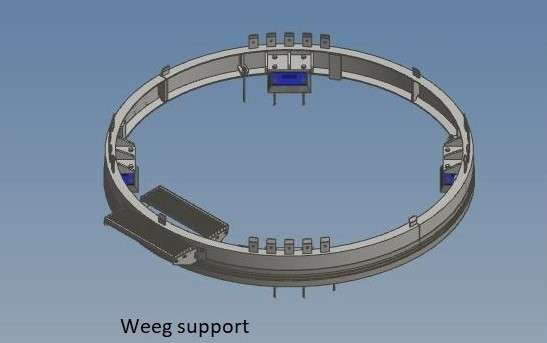

Improve your inventory management with innovative weighing support for silos

Do you want to know exactly how much product you have in stock? Are you looking for a hygienic and low-maintenance weighing solution for your silos? Polem's innovative weighing support for silos with a diameter of Ø2800 to Ø3500 mm offers you the perfect solution. With a weighing capacity of up to 120 tons (4x 30 tons), you get accurate measurements that significantly improve your inventory management.Why choose advanced weighing support for your silos?As a business owner or operations manager, you know that accurate inventory management is crucial for efficient business processes. Reliable weighing support makes the difference between guesswork and exact knowledge about your inventory. With Polem's innovative weighing support systems, you benefit from significantly shorter installation times, improved working conditions, and optimal silo performance.The smart design with weighing consoles on the inside of the UNP ring lowers the construction height, resulting in an access door of only 380 mm high. This makes your daily operations considerably easier.Six ways innovative weighing support directly benefits your businessThe advanced weighing support translates into concrete benefits for your daily operations:Save on installation costs: thanks to one type of profile (UNP240), installation is faster and more efficient, lowering your project costsIncrease employee safety: the solid construction guarantees stability and reliability without compromising on safetyEnjoy a sleeker and more professional design: the improved weighing console placement ensures a more aesthetically pleasing resultWork more comfortably around your silos: the absence of an internal frame gives you more freedom of movement and easier equipment placementReduce the risk of work-related injuries: the low construction (380 mm) allows access without stairs or railingsSimplify your maintenance work: the built-in lift-off system reduces loose parts and simplifies conduit feed-throughsEffortlessly meet hygiene requirements in the food industryDo you work in the food industry? Then you're familiar with the strict hygiene requirements. With Polem's weighing support, you effortlessly meet these standards:Reduce the risk of product contamination: the superior sealing beneath the ring prevents material accumulation and simplifies your maintenance workLower your cleaning costs: the optimal cleanability reduces labor hours for cleaning and ensures a hygienically responsible working environmentPrevent costly contamination problems: the special silo sealing band (developed with Sidijk) offers easy positioning thanks to Velcro and perfect sealing through sturdy tie-down strapsExtend the lifespan of your investment with seamless composite silosWhy settle for less than the best when it comes to your storage systems? Polem's weighing support systems are perfectly matched to high-quality composite silos that offer you concrete advantages:✅ Save significantly on maintenance costs: composite silos are corrosion-resistant and require less maintenance than traditional materials✅ Prevent product loss and contamination: the seamless, mirror-smooth construction ensures your products flow out completely without residual remains✅ Optimally protect your products against moisture: the superior insulation properties of composite protect your valuable raw materialsWith more than 50 years of experience in seamless, strong, and mirror-smooth composite silos, Polem guarantees you a long-lasting, reliable solution for all your storage needs.Start optimizing your storage systems todayYou want to get the most out of your investments. With Polem as your partner, you gain access to the latest innovations in bulk storage that directly contribute to your business results. Whether you work in the food industry, agricultural sector, or other industries with specific storage needs - you deserve solutions that precisely meet your requirements.Polem's weighing support systems offer you:Accurate inventory control for better planningEasier daily use through smart designLower maintenance costs thanks to sustainable qualityBetter hygiene for safer productsProfessional appearance of your facilitiesDiscover for yourself how Polem's innovative weighing support systems can improve your operational processes. Request a free consultation today.

Composite silos and tanks for the food industry: premium storage solutions with seamless quality

Premium storage for optimal product quality in food and beverage productionAre you looking for the best storage solutions for your food business? Seamless composite silos and tanks offer you the perfect combination of hygiene, durability, and efficiency. These premium storage systems have been guaranteeing the highest quality for every grain and every drop in the food production process for more than 50 years.What makes composite silos and tanks ideal for food storage?Hygienic benefits of seamless composite storageFood producers are increasingly choosing composite storage systems due to their unique hygienic properties. The completely seamless construction and mirror-smooth inner wall ensure:No accumulation of food residues - the smooth walls prevent product from stickingMinimal microbial growth - no crevices or seams where bacteria can growEasy cleaning - the smooth surface can be cleaned quickly and thoroughlyNo contamination - the inert material does not react with food productsSustainable material benefits for food producersComposite storage offers substantial advantages over traditional materials such as steel or concrete:Corrosion-resistant - no rust formation or degradation, even with salt-containing productsExcellent thermal insulation - protects your product against temperature fluctuationsStrength comparable to steel - complete structural integrity without corrosion riskMinimum 20-year lifespan - proven durability under normal operating conditionsProven practical applications in the food industryDry ingredient storageComposite silos are ideal for storing various dry ingredients:Flour, meal, and bread mixesSugar and sweetenersBakery ingredientsRice, grains, and grain derivativesStarch and starch productsSalt and spicesPowdered milk and dairy derivativesCocoa powder and chocolate preparationsLiquid food storageTanks made of composite material offer excellent performance for:Vegetable oils and fatsMilk and dairy productsFruit juices and concentratesBeverage syrupsSauces and dressingsWater and process waterFermentation processesMeasurable business benefits for food producersEnhanced operational efficiencyThe advanced properties of composite storage translate directly into tangible business benefits:Improved product flow - up to 30% less product accumulation thanks to the smooth wallsReduced cleaning time - up to 40% less time needed for effective cleaningReduced downtime - significantly fewer interruptions due to maintenanceConsistent product temperature - up to 8 times better insulation value than steelROI-improving cost savingsInvesting in composite storage leads to demonstrable cost savings:Reduced energy costs thanks to superior insulation propertiesLess production loss due to optimal, complete outflowReduced maintenance costs over the entire service lifeLonger lifespan resulting in a better total investmentCustom storage solutions for every food producerTailored configurationEvery food producer has unique requirements. That's why we offer fully configurable storage systems:Capacity - from 20 to 1500 m³ storage volumeProduct-specific designs - adapted to the flow characteristics of your productIntegration options - seamless connection to existing production systemsAccessories - vibrating bottoms, heating systems, and measuring instrumentsExpert support throughout the entire lifecycleAs a partner in food storage, we offer support that goes beyond the initial installation:✅ Specialized advice - expert support from food industry specialists✅ Professional installation - skilled placement by certified technicians✅ Technical documentation - comprehensive manuals and specifications✅ EXPERT check service - preventive maintenance program for maximum lifespanAdvanced safety and quality standardsCertifications and complianceOur storage systems meet the strictest standards for the food industry:ISO 9001 certified production processesEU 1935/2004 compliant for materials in contact with foodHACCP compatible designsEHEDG hygienic design principlesStart optimizing your food storage todayAre you ready to improve your product quality and operational efficiency? Our market specialists are ready to discuss your specific storage needs and offer a tailored solution.Contact us for a free consultation or call one of our experts.Every grain, every drop. Quality in, quality out.

Proud of our partnership with ForFarmers during their challenging silo renovation in Deventer!

At the heart of the ForFarmers factory in Deventer, a team faced an extraordinary challenge: replacing a 40-year-old indoor silo in the middle of an operational production process. A complex operation that was not only technically challenging but also required strict safety measures. As a specialist in high-quality composite storage solutions, Polem was proud to be part of this project.The challenge: renovating in a 'high-risk area'The silo that needed renovation was located in the raw materials block, in the middle of the production process. What made this job particularly complex was that the silo was used for the temporary storage of warm and moist 'startup product' - a flammable material with residues remaining in the silo. Moreover, a floor and a roof extension rested on the silo.According to the inspection by a certified mill builder, the 40-year-old silo showed clear signs of wear due to the abrasive action of the product. Additionally, the combination of heat and moisture had caused corrosion formation under the coating.The solution: seamless composite silosAfter careful consideration, ForFarmers decided not to replace the silo walls but opted for a more innovative approach: placing round polyester silos within the framework of the existing square silo. To make this possible, an opening was made in the facade through which the round silo parts could be brought in one by one."The fact that polyester is more resistant to corrosion under the influence of heat and moisture than steel needs no explanation," says Harry Tragter, plant manager at ForFarmers. "But there are more arguments in favor of smaller polyester silos. Instead of one silo, there are now four silos available. This expansion offers great operational advantages. The total storage capacity is somewhat smaller, but the extra silos offer much more flexibility."Safety as top priorityAt ForFarmers, safety is always the top priority. Specific safety measures were taken for this project, including:Thorough cleaning of the silo and silo wallsAvoiding 'hot work activities' such as welding where possibleApplication of water atomization where necessaryOrganization of safety supervision and engagement of a fire watchTemporary production stops during high-risk activitiesRoeland Dinkelman, technical team leader at ForFarmers, emphasizes the importance of these measures: "Various preventive measures and different activities were necessary for the safe execution of the project, including the preparation of safety analyses and safety plans."A successful collaborationThe renovation project was a joint effort by ForFarmers, Peree Bouwadvies, Van Mourik Group, and Polem. Thanks to this collaboration and the expertise of ForFarmers' safety team, the complicated project was successfully completed.Project leader Erik Kuiper of ForFarmers is satisfied with the result: "Valuable experience has been gained with the project, which can be applied again in similar projects within the organization."Why choose composite silos from Polem?The choice for our composite silos in this project illustrates the advantages these solutions offer:Corrosion resistance: Our silos are resistant to aggressive substances, heat, and moistureSeamless construction: No weak spots or risk of leakageLong lifespan: Minimal maintenance for decades of useCustomization possible: Adapted to the specific requirements of your location and processesOperational flexibility: Multiple smaller silos offer more storage flexibilityAt Polem, we continue to innovate and collaborate with partners like ForFarmers to provide safe, sustainable, and efficient storage solutions for the most challenging situations.Interested in what Polem can mean for your storage needs? Feel free to contact our market specialists.http:// https://www.bulkgids.nl/opslag/succesvolle-en-veilige-renovatie-van-grondstofsilo-bij-forfarmers/

Closed during Easter

We would like to inform you that our branch in Lemmer will be closed on Friday, April 18 (Good Friday) and Monday, April 21 (Easter Monday).From Tuesday, April 22, our staff will be available again to answer your questions about premium silos and tanks.Discover Polem during the Easter holidaysEven during our closure, please visit our website for information about our products and services. View our extensive range of seamless, strong and mirror-smooth composite silos and tanks, or learn more about our areas of expertise in different market sectors.What can you do during our closure?Put together your silo or tank with our online configuratorFill out the contact form for a response after the holidaysView our reference projects to see how Polem contributes to quality in, quality outLearn more about our service, inspection and maintenance capabilitiesSince 1972, we have stood for premium quality without compromises. After Easter, we look forward to helping you personally again.We wish you a pleasant Easter.Team Polem

Seamless, strong and mirror-smooth: premium storage for your processes

The facts speak for themselvesSince 1972, Polem has been delivering composite silos and tanks that make no compromises when it comes to quality. Our storage systems are designed for companies that value continuity and reliability in their production processes.The difference you can see immediatelyOur composite silos and tanks stand out on three essential points:Seamless: Our unique construction eliminates connections where product can accumulateStrong: Durable protection against both internal and external influencesMirror-smooth: Optimal product flow and easy cleaningThe return on qualityPolem's composite silos and tanks offer direct benefits for your business results:Less downtime in your processesReduction of product loss due to accumulationLower maintenance costsLonger lifespan than conventional alternativesA proven solution for every industrial applicationOur technical expertise ensures the right flow in every process:✅ 40° hoppers for optimal mass flow in food applications✅ 60° hoppers for abrasive materials such as fertilizer or cement✅ Custom solutions up to 1,500 m³ and diameters up to 9 metersThe security of a future-proof choiceAt Polem, we don't build for the short term. This perspective is reflected in every aspect of our silos and tanks - designed for decades of reliable service.Experience the Polem difference for yourselfOur market specialists are happy to think along with you about a customized solution that perfectly matches your process. Discover for yourself why many leading companies choose Polem.Every grain and every drop counts. Quality in, quality out.It's not a silo or a tank. It's a Polem.

Girlsday at Polem - The future of technology is female!

Today at Polem was all about Girls' Day, an initiative to get girls excited about the world of technology - and of course we are happy to contribute!We welcomed no fewer than 22 girls from the Zuyderzee Lyceum secondary school in Lemmer for an inspiring tour of our company. They were given a look behind the scenes of our production of composite silos and tanks, as well as getting to work themselves with a fun technical activity.As far as we are concerned, these are the future technicians, engineers and craftswomen who will make the difference Thank you girls, for your enthusiasm and curiosity. And of course, a shout-out to the teachers and supervisors at Zuyderzee Lyceum for their efforts. Here's to a bright future with more women in engineering!

Optimize your fertilizer storage: How premium silos and tanks save you time and money

Rising fertilizer prices are forcing agricultural entrepreneurs to adopt smarter storage strategies. With the right fertilizer silo or tank, you not only save time during the spreading season but also benefit from more favorable purchase prices. Discover how high-quality composite storage solutions can increase your business efficiency.The right storage solution for every situationWhether you choose granular fertilizer or liquid fertilizers, there are suitable storage solutions for both variants:For granular fertilizer: Seamless hopper silos ensure optimal outflow and prevent condensation, which is essential when storing fertilizer.For liquid fertilizers: High-quality tanks are perfect for storing liquid nitrogen and other liquid fertilizers, with capacities of up to 35,000 liters per tank.Practical experiencesDairy farmer Cees Ruijter, Warmenhuizen: "Our new fertilizer silo halves our working time! Within 30 seconds, our spreader is filled with two tons of fertilizer. No more hassle with storage, and the investment pays for itself quickly through time savings and purchasing advantages."Arable farmers Hein and Lenus Waalkens, Nieuwolda: "Since we chose premium composite tanks, WE determine when to buy, not the market. We now dose with milliliter precision, even in stormy Groningen weather. No maintenance, perfect landscape integration, and complete control over our business costs. The best investment of recent years!"Benefits of composite fertilizer silos and tanksSeamless construction: Prevents fertilizer buildup and guarantees consistent outflowCorrosion-resistant material: Immune to the aggressive properties of fertilizerOptimal insulation: Prevents condensation and clumpingCustomization possible: Available in various sizes, heights, and colorsLong-term investment: Minimum lifespan of 20-25 yearsMinimal maintenance: Low operational costs over the entire lifespanFinancial benefitsHaving your own fertilizer silo or tank allows you to:✅ Purchase fertilizer during pre-sales at more favorable prices✅ Be independent of delivery times during the busy spreading season✅ Save on the costs of big bags and the associated waste✅ Work more efficiently with less manual labor and time lossInvesting now means being preparedThe right time to invest in a new fertilizer silo or tank is now. This way, you are optimally prepared for the upcoming spreading season and can benefit from favorable purchasing moments.Prepare for an efficient and profitable spreading season with a safe and reliable storage solution from Polem!Would you like more information about our fertilizer silos or tanks for liquid fertilizers? Contact our market specialists for a no-obligation consultation.

Optimal de-icing begins with reliable storage solutions

When temperatures drop below freezing, every minute counts. Road managers who cannot deploy within 30 minutes risk unsafe roads and accidents. Effective de-icing therefore begins not on the road, but at your storage facilities, where spreading salt and brine must be ready for use at all times—regardless of circumstances.The challenges of salt storageSpreading salt and brine are natural enemies of conventional metal storage systems. In practice, we regularly see silos showing severe corrosion damage after just 5-7 years, despite being designed for a lifespan of 15+ years. Even stainless steel cannot withstand the aggressive effects of salt solutions on connection pieces and moving parts. Additionally, condensation in the silo can lead to bridging of the salt, preventing proper flow. This creates operational problems precisely when you need the material most.The solution lies in corrosion-resistant storage systems specifically designed for the challenging properties of de-icing materials.Advantages of composites for salt storageComposite (GRP) offers significant advantages for storing spreading salt and brine:Absolute corrosion resistance: Unlike metal or concrete, salt does not attack the molecular structure of composite—even after decades of intensive useSeamless construction: The smooth, seamless inner wall ensures optimal product dischargeSuperior insulation: The natural insulating properties reduce condensation and prevent bridgingLong lifespan: Minimal maintenance and exceptional durability mean lower total ownership costsWet salt technology: more efficient and environmentally friendlyThe transition to wet salt technology is a game-changer in modern de-icing. By pre-mixing dry salt with brine, the thawing reaction is activated up to 15 minutes faster. Moreover, the spreading amount can be reduced by 20-30% with equal effectiveness, resulting in less environmental impact and lower costs.This advanced method requires both salt silos and brine tanks, often in combination with salt dissolving systems. The complete system ensures an efficient, environmentally responsible approach to de-icing.Customized solutions for every situationYour specific situation requires an appropriate solution:For municipalities: Compact systems that fit within existing municipal yards, with quick access for spreading vehiclesFor provincial services: High-capacity systems that can handle peak moments when the entire road network needs treatment simultaneouslyFor private enterprises: Cost-efficient, scalable solutions that guarantee safety without excess capacityA complete system can consist of:Fixed silos with capacities from 20 to 250 m³Mobile silos for locations where a permanent installation is not possibleBrine tanks in vertical or horizontal designs (20 to 300 m³)Salt dissolving systems for making brineAssociated platforms, drainage systems, and filling installationsPeriodic InspectionPrevention is always more advantageous than repair. An expert check costs only a fraction of what a failure during a winter peak can cost you—not only in repair costs but especially in operational delays when safety is at stake. With a periodic expert check, you can ensure your system always remains functioning reliably. This inspection includes:✅ Thorough inspection of all components✅ Measurement of wall thickness and material strength✅ Evaluation of ventilation provisions✅ Inventory of any wear or damage✅ Professional advice on maintenance and optimizationBy including an expert check in your maintenance plan, you ensure operational safety and maximize the lifespan of your investment.Choosing the right partnerYou can recognize the right partner for your de-icing solutions by:Proven results – Ask for reference projects that have been operational for at least 10 yearsTurnkey thinking – A partner who not only delivers but thinks along about the entire process of de-icingQuality certification – Look for ISO certifications specific to composite processingService orientation – Good support during the winter season is not a luxury but a necessityInnovation capacity – A partner who invests in R&D for increasingly sustainable solutionsComposite silos and tanks remain the gold standard for salt and brine storage, with their unique combination of durability, functionality, and low maintenance costs. With the right systems, you're not only investing in safe roads but also in a long-term solution that continues to function reliably year after year, even under the most challenging winter conditions.Are you ready for the next winter period? Let one of our specialists analyze your current situation without obligation. In a brief conversation, we'll map out your specific challenges and advise on possible optimizations—often achievable before the first frost. Contact us today for a free consultation.

Dust explosion safety: the importance of explosion panels in storage silos

When storing bulk goods and dust explosion hazardous products, safety always comes first. Effective explosion panels are an essential safety feature for any industrial silo. In this blog, we explain why explosion panels are crucial, what the advantage is of domed silo roofs, and how this combination maximizes safety.Explosion panels: essential protection against dust explosionsExplosion panels are advanced safety devices specifically designed to discharge built-up pressure in a controlled and safe manner during a dust explosion in a silo. The function of these panels is crucial:They limit or prevent serious damage to the siloThey protect surrounding infrastructure and equipmentThey minimize the risk of fire and personal injuryThey prevent a primary explosion from leading to a chain reactionDomed silo roofs: superior dust explosion safetyPolem produces silo roofs in a standard domed klöpperboden shape. This design offers significant safety advantages over the "chinese hat" shape often used in conventional metal silos:1. Increased pressure resistanceThanks to the optimally designed domed shape, the silo roofs can withstand a p-red of 1.0 bar. This technical advantage is essential for silos in which dust explosion hazardous products are stored. In comparison: metal silos typically withstand a p-red of only 0.5 bar maximum.2. More efficient placement of explosion panelsThe increased p-red value means that less surface area is needed for pressure relief. For composite silos, this means that all required explosion panels can be fully integrated into the roof, while metal constructions often need wall panels as well.Three concrete benefits for your operationsThis technical advantage translates into direct operational benefits:Maximum storage capacity: You can utilize the full capacity of the silo without having to account for a maximum fill level below wall explosion panels. This maximizes your storage efficiency and reduces the cost per ton of stored product.Improved hygiene: The design without flanges in the wall eliminates potential problem zones where product can accumulate. This significantly reduces the risks of mold formation, product spoilage, and bacterial growth – crucial for applications in the food and pharmaceutical industries.More compact construction height: Unlike metal silos, which often need to be built higher to accommodate wall explosion panels, composite silos with roof-integrated panels allow for a lower construction height – an advantage when applying for permits or in buildings with height restrictions.Professional installation for optimal safetyFor maximum protection, explosion panels are always installed flush (completely flat) with the inside of the roof. This seamless integration ensures that in the event of a dust explosion, the built-up pressure can escape immediately and with minimal resistance.As standard, these safety systems are equipped with robust safety railings. This essential addition prevents maintenance personnel from inadvertently standing on the vulnerable panels during inspection or maintenance operations.Specialized indoor installationsFor silos placed inside a building, additional safety requirements apply. In these situations, specially designed vent ducts are required. For these indoor installations, the explosion panels are always constructed in a round shape.This round shape is not an aesthetic choice but a technical necessity: rectangular or square explosion ducts must be extremely heavy-duty to guarantee the required pressure resistance, which is costly and often practically unfeasible.Responsibility and expertiseAccording to legislation, it is the responsibility of the client to determine whether the stored product is dust explosion hazardous and whether the silo should be equipped with appropriate explosion panels. Polem's market specialists are ready to advise on this and develop a safety solution that perfectly fits your specific situation.Every grain, every drop. Quality in, quality out.