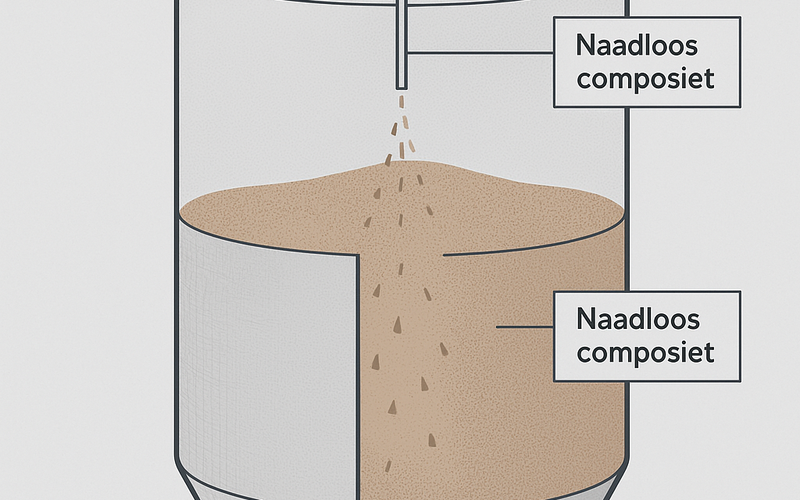

Sustainable salt storage for winter services: optimal performance with composite tanks

In winter, every minute counts. Roads, cycle paths and business parks must remain safe. Reliable salt storage is therefore essential. However, traditional solutions such as steel tanks or silos cause problems in the long term: corrosion, high maintenance costs and failures at crucial moments.With Polem composite tanks, you prevent these risks. Our tanks are designed for sustainable salt storage and offer the ideal solution for modern de-icing operations.Why more and more municipalities and road authorities choose compositeComposite (glass fiber reinforced plastic, GRP) is the material for future-oriented storage. It is seamless, strong, mirror-smooth and immune to corrosion. Perfect for storing brine and road salt.Moreover, our tanks have naturally excellent insulating properties. This keeps the spreading material in optimal condition, without condensation or freezing risks. This ensures your inventory is always ready for use — essential during peak winter periods.Key advantages:Resistant to corrosionMinimal risk of condensation and freezingLong service life with minimal maintenance costsLightweight: simple and fast installationOptimal product flow, even at low temperaturesEfficient deployment of gritting vehicles, without blockagesTechnical specifications that make the differenceSalt dissolvers: proven technology for brine production Polem supplies complete salt dissolution systems that produce brine of consistent quality. These installations were developed in collaboration with Akzo Zout Nederland B.V.Technical characteristics of our salt dissolvers:✅ Brine concentration of 23.3% (standard NaCl brine)✅ Practical delivery of 300 grams of salt per liter (± 25% brine)✅ Filter bottom with 3-layer gravel system for pure brineMobile versus fixed solutionsFlexibility where you need it If a fixed silo solution at your location is not an option due to inspection regulations, Polem can also supply you with a mobile silo. These do not need to be placed on a concrete foundation, providing extra flexibility for various applications.Preventive maintenance for maximum reliabilityPolem Expert Check for winter services With our Expert Check service, certified technicians carry out annual inspections. We check wall thickness with special measuring equipment and assess the hardness of the GRP material. You receive a comprehensive report with photos and recommendations.This prevents unexpected repairs during critical winter periods.The impact on your daily practiceWith a Polem composite tank, your de-icing operations run smoothly. No downtime due to unexpected repairs. No quality loss of brine or salt. No unnecessary cleaning times or expensive maintenance sessions.In addition, you significantly reduce the total cost of ownership. The investment in a composite tank pays for itself through years of worry-free use.Proven sustainabilityEnvironmentally friendly propertiesBrine adheres better to the road surface than dry saltFaster thawing action because it doesn't need to dissolve firstLess material ends up in verges or the environmentPrecise dosing possible for efficient salt useReady for your next winter season?Every situation requires customization. Whether it concerns fixed storage at municipal depots or mobile solutions for temporary locations, Polem develops and delivers tanks that perfectly match your requirements and processes.Our specialists think along with you. This way you are ready for the next winter, no matter how severe it may be.Sustainable storage solutions for de-icing operations. Every grain, every drop. Quality in, quality out.

.png)

Polem Walking Day 2025

Tradition and team spirit on the longest day of the year.On Thursday, June 19th, it was time once again for the annual Polem Walking Day. A tradition that started years ago with a small group of colleagues who decided to walk to work on the longest day of the year. It has now become a firmly established part of the company culture.As usual, the participants gathered early in the morning in Sloten. At 5:15 AM sharp, the walk to Lemmer began. Along the way, everyone enjoyed the beautiful Frisian landscape and each other’s company.Halfway through the walk, a well-prepared breakfast was waiting — kindly arranged by two colleagues who volunteered to take care of everything. A perfect moment for a short break and connection.The atmosphere throughout the walk was excellent. At Polem, teamwork isn’t just about what happens at work — it’s also about moments like this. The team spirit could be felt with every step.Preparations for the next edition can already begin.

Smarter water management in fish processing: Noordzee International chooses storage tanks from Polem

oordzee International in Urk is making its production process more sustainable. In collaboration with Polem, the fish processing company installed four custom-made storage tanks for the reuse of purified wastewater. The result: less waste, lower costs, and a more stable production process.Water plays a crucial role in fish processing — for cleaning, cooling, and hygiene. Previously, most of the used water was discharged. Now, it is purified, stored, and reused where possible.Polem’s composite tanks are seamless, easy to clean, and fully compliant with the strict hygiene standards of the food industry. Thanks to smart integration with the existing water management system, production continued without disruption during installation.Results for Noordzee International:Reduced water consumptionLower operational costsIncreased sustainabilityGreater flexibility in production"Thanks to the tanks from Polem, we now use water much more efficiently. This supports our sustainability goals and lowers costs," says Noordzee International.Curious how custom storage tanks can make your process more sustainable? Contact Polem. Our specialists are happy to advise you.

Explosion-safe bulk storage with composite silos: safety in every layer

In industrial environments where powders and liquids are stored, safety is paramount. Explosive substances such as flour, sugar, starch, and chemical powders require specialized storage solutions that meet the strictest safety standards. Polem develops composite silos that not only provide optimal protection but also ensure long service life and minimal downtime.Why explosion safety is crucial in bulk storageWhen storing dust explosion-hazardous products, one of the greatest risks is the domino effect. This occurs when an initial explosion triggers a chain of subsequent explosions. While the first explosion is often not catastrophic, the third or subsequent explosions usually cause the greatest damage.In silo parks, where silos are often interconnected through combined filling systems, ventilation systems, extraction installations, or filter systems, dust explosions can spread at lightning speed. This emphasizes the importance of adequate preventive measures in the design of storage systems.Explosion safety according to ATEX guidelinesIt is the responsibility of the client to determine whether the product stored in a silo is dust explosion-hazardous. The client must determine whether the silo should be equipped with explosion panels or other protective measures.Strict European ATEX guidelines apply to explosive environments. ATEX zones are defined as follows: zones 20, 21, and 22 for dust explosion hazards and zones 0, 1, and 2 for gas explosion hazards. Polem's composite silos are specifically designed to comply with these ATEX requirements.Composite: the ideal material for explosion-safe storageSeamless construction prevents risk pointsA Polem silo or tank is seamless, strong, and mirror-smooth thanks to powerful composite materials. Immune to corrosion, protective against moisture, and easier to maintain than traditional materials. This seamless construction is crucial for explosion safety because there are no welds or connections where dust can accumulate and ignition sources can occur.Superior roof construction for safe pressure reliefPolem produces silo roofs as standard in a domed shape (Klöpperbodem). This roof shape offers important advantages over the "Chinese hat" shape often used with metal silos. Due to the domed shape, Polem silo roofs can be designed for a P-red of 1.0 bar. This is essential for silos storing dust explosion-hazardous products and equipped with explosion panels.Metal silos can typically only handle a P-red ≤ 0.5 bar. A higher P-red means less relief surface area needed for explosion panels. With Polem silos, this can usually be realized entirely in the roof, while with metal silos, the silo wall often needs to be utilized as well.Integrated explosion protectionExplosion panels: safe pressure reliefExplosion panels are essential safety devices that ensure that in the event of a dust explosion in a silo, the explosion pressure is discharged in a controlled and safe manner. This prevents major damage to the silo and surroundings, as well as possible fire or serious personal injury.The flanges for explosion panels are always laminated flush with the inside of the roof, so that in the event of a dust explosion, the built-up pressure can escape quickly and with minimal resistance through the explosion panels.Rupture detectors and maintenanceExplosion panels are usually equipped with rupture detectors. These give a signal when a panel has opened. The panel and rupture detector must be replaced immediately in that case, because an open connection to the outside air can cause dust dispersion, moisture, rain, and other contamination in the silo.Innovative grounding system for electrostatic safetyCertified safetyPolem's grounding installation was developed in cooperation with ISMA (Kontich, Belgium), a recognized authority in the field of grounding systems. ISMA has certified Polem composite silos with grounding installation as suitable for storing products that pose dust explosion hazards.Advanced technical specificationsThe current generation of grounding rods is made of special stainless steel spring steel, which offers significant advantages: one-piece construction without weld connections, eliminating the risk of breakage and damage from loose parts in the silo or transport systems, reduced forces due to the smaller surface area of the new grounding rods, and flexible suspension where the grounding rods hang freely on the inside of the roof and follow the flow pattern of the product in the silo.Polem's new grounding system offers maximum safety for explosive bulk materials, a hygienic design without product accumulation with flat stainless steel screw plug and open fork connection, reliable and robust construction of high-quality materials, and easy inspection and maintenance thanks to the flexible design.Long-term benefits of composite in explosion-safe applicationsDurability and ease of maintenanceWe deliberately choose glass fiber reinforced plastic (GRP). It is lightweight, strong, corrosion-resistant, and low-maintenance. This allows us to build silos and tanks that last longer, cause less downtime, and meet requirements for food safety, ATEX, and sustainability.Minimal maintenance costsOur silos and tanks are seamlessly produced, strong, and mirror-smooth. Every product with us meets not only general standards but also our own standards. That bar is set just a little higher. This quality standard translates directly into lower maintenance costs and more reliable operation throughout the entire service life.Custom solutions for optimal safetyOur products are seamlessly produced, strong, and tailored to the customer's process. No standard solutions, but custom work: focused on application, location, and sector. Every Polem silo is fully custom-designed, taking into account the specific properties of the stored product, process conditions, and applicable safety standards.Conclusion: investing in safety and continuityExplosion-safe bulk storage requires more than just compliance with regulations – it requires an integrated approach where safety, sustainability, and operational security come together. Premium means uncompromising quality for us. In our production hall, you can see the craftsmanship. The attention to every detail makes the difference for customers.Polem's composite silos with integrated explosion protection and innovative grounding systems not only provide maximum safety but also ensure low maintenance costs, long service life, and minimal downtime.It's not a silo or tank. It's a Polem.Every grain, every drop. Quality in, quality out.Would you like to increase the safety of your bulk storage while investing in sustainability and operational security? Contact our specialists for a no-obligation consultation about explosion-safe storage solutions that perfectly match your specific needs.

.jpg)

Custom composite silos: the smart choice for agricultural storage

In the agricultural sector, every minute and every grain counts. If you work with animal feed, fertilizer or other agricultural materials, you know how crucial it is that your storage solution is not just practical, but also hygienic, durable and efficient. That’s exactly what Polem’s composite silos offer.Hygienic and food-safeA Polem silo is seamless, strong and ultra-smooth. Thanks to the smooth interior, product residues barely remain, and the risk of bacterial or mold growth is minimized. Your products stay fresh longer, and the FIFO principle (first in, first out) is naturally guaranteed. That’s better for your product – and for your animals.Poultry farmer Udo Baumeister from Germany confirms:“Always perfect feed and no segregation. In the house with the horizontal floor, we see higher laying percentages and better feed conversion.”Lightweight, strong and insulatingComposite is significantly lighter than steel, making it easier to transport and install. At the same time, it is extremely durable and built to last for decades. Its natural insulating properties protect your product from temperature fluctuations and prevent condensation – a common issue in steel silos.Dairy farmer Cees Ruijter from the Netherlands shares:“In winter, fertilizer continues to flow well from the silo. A solid investment that saves us time and hassle.”Tailored with the configuratorWith the Polem configurator, you can easily design your ideal silo: diameter, capacity, outlet and colour – all tailored to your business and needs. This gives you maximum flexibility with the assurance of long-term reliability.For every agricultural applicationOur silos are perfectly suited for:storage of feed, grain, premixes or mineralsstorage of fertilizer, lime or other nutrientswater storage on your farmproducts sensitive to segregationWe offer silos with horizontal or conical floors, optionally equipped with vibrating bases or air-assist systems – fully adapted to the specific properties of your product.Our market specialists are ready to advise you on the ideal setup for your situation.Three reasons to choose Polem1. Hygiene and safetyUltra-smooth, seamless construction. no residue. no bacterial growth.2. Durability and maintenanceCorrosion-resistant, insulating and virtually maintenance-free. lifespan up to 30 years.3. Flexibility and customizationUp to 1,500 m³. available in any RAL colour. tailored to your logistics and farm layout.Discover what Polem can do for your businessWould you like to know which silo best suits your needs? Contact one of our market specialists or design your silo directly with our configurator.It’s not just a silo or tank. it’s a Polem.

_1.png)

From steel to composite: why companies are switching to Polem

Discover why glass fiber reinforced plastic (GRP) silos and tanks are the future of industrial storageThe silent revolution in storage technologyIn sectors where food safety, sustainability and operational reliability are essential, a silent revolution is taking place. More and more companies are consciously making the switch from traditional steel silos to modern composite storage solutions. But why are they choosing Polem?With more than 50 years of experience in developing glass fiber reinforced plastic (GRP), Polem has established itself as a market leader. Our custom solutions are not only technically superior, but also offer concrete business advantages that directly translate into lower costs and higher reliability.Interest: the power of composite vs traditional materials1. Sustainable and maintenance-friendly: your investment protectedGRP is naturally resistant to corrosion, chemical attack and weather conditions. Where steel silos show signs of rust and degradation after just a few years, our composite solutions maintain their structural integrity for 20-30 years.The smooth interior surface of our silos not only makes cleaning easier, but also significantly reduces the risk of bacterial or mold formation. This is crucial in sectors such as the food industry and animal feed sector.Your advantages:✅ Less maintenance - Up to 60% lower maintenance costs✅ Longer lifespan - 20-30 years versus 10-15 years for steel✅ Resistant to aggressive substances and weather conditions2. Food-safe and certified: compliance without worriesOur composite silos and tanks are certified according to EC 1935/2004 and EU 10/2011. These certifications guarantee that our products are safe for direct contact with food - an absolute requirement in modern food production.The seamless and mirror-smooth interior surface not only prevents product residues, but also eliminates potential breeding grounds for bacteria. For companies in the food & feed sector, this means less risk of contamination and higher product quality.Why this matters:✅ Certified for food contact - Full compliance✅ Smooth and seamless interior surface - No corners where bacteria can settle✅ Reduced contamination risk - Protection of your product quality3. Smart configurator: custom solutions within reachWith our online configurator, customers can easily assemble their own silo or tank. From capacity and diameter to specific connections and accessories - everything is configurable. This innovative tool not only accelerates the quotation process but also ensures complete transparency in pricing.Direct benefit:✅ Immediate insight into possibilities and prices✅ Accelerated quotation process - From configuration to quote in 24 hours✅ Custom solutions - Exactly what you needDesire: proven results worldwideGlobal applications, local expertisePolem silos and tanks are deployed in more than 50 countries and diverse markets: from food and feed to chemicals, biogas and winter road maintenance. This broad application proves the versatility and reliability of our GRP technology.Whether you work with:Food products (milk powder, grains, sugar)Animal feed (compound feed, raw materials)Chemicals (aggressive substances, ATEX environments)Winter services (road salt, brine)Biogas (biomass, digestate)Polem has the expertise and experience to deliver the perfect storage solution.Expert Check: preventive maintenance that pays for itselfFor optimal long-term performance, Polem offers Expert Checks: periodic inspections that detect wear early. Analyses from our service database show that customers experience:Less downtimeLonger lifespanLower maintenance costsThe result: More operational security, fewer unexpected costs.Your next step to better storageWhy switch to Polem now?The numbers don't lie. Companies choosing Polem composite silos experience:Lower total cost of ownership through minimal maintenanceHigher operational reliability through dependable performanceBetter compliance through certified food safetyFaster ROI through longer lifespanPolem delivers more than storage - we deliver certaintyWith high-quality composite solutions, we ensure that:✅ Raw materials are optimally protected✅ Processes continue running reliably✅ You can trust in a long lifespan with minimal maintenance requirementsIt's not just storage. It's Polem.Start today with your ideal storage solutionReady to experience the benefits of composite storage? Please contact one of our market specialists.

.png)

No project is the same. That's why no Polem is standard.

Custom silos and tanks: why one size doesn't fit allEvery industry, every application, and every product is different. So why should your silo or tank be standard? At Polem, we don't believe in one-size-fits-all solutions. Whether it's salt, starch, milk powder, or biogas: we design and build every silo or tank to measure. Precisely tailored to your situation, your product, and your process.Custom solutions as our foundation: from drawing to deliveryFrom the first sketch to the last bolt. Everything starts with your requirements. Our composite silos and tanks are available in any size up to 1,500 m³, in any RAL color, with or without insulation, suitable for ATEX environments, with specific discharge systems, or equipped with integrated platforms and level indicators.Why custom solutions for silos and tanks?Because a wrong connection, uneven filling, or poorly flowing product costs a lot of money. And because the right flow isn't coincidence, but the result of smart choices. That's why at Polem we make silos and tanks that truly fit. Functional, safe, and sustainable.Every grain, every drop counts. Premium quality means uncompromising quality to us. In our production hall, you see the craftsmanship. The attention to every detail makes the difference for customers.Composite makes custom solutions possibleComposite is our material. Because it's lighter than steel, insulates better, doesn't corrode, and can be processed seamlessly. This enables us to create strong, low-maintenance storage solutions that last for decades – and effortlessly grow with your production.The advantages of composite custom solutions:Seamless and mirror-smooth - For optimal product flow and minimal residueCorrosion-resistant - Resistant to aggressive substances and environmentsSuperior insulation - Protects against condensation and temperature differencesFood-safe - Meets the strictest standards (EU1935/2004)Low-maintenance - Less downtime, lower costsFast installation - Ready to use immediately, minimal downtimeCustom solutions per sector: each market segment requires specific knowledgeFood & Feed: where food safety and hygiene are centralFor food and animal feed producers, safety is non-negotiable. Our custom silos for this sector are:Certified food-safe according to EU1935/2004Seamlessly manufactured to prevent bacterial formationOptimized for flow behavior with 40° hoppers for mass flow (FIFO principle)Equipped with vibrating cones for difficult-flowing productsChemical: safety without compromise with aggressive substancesFor the chemical industry, we deliver custom tanks that withstand the toughest conditions:Chemically resistant resins for aggressive substancesDouble-wall construction with leak detection systemATEX-compliant design for explosive environmentsSpecific connections for process equipmentAgricultural: reliable storage for the farmFor agricultural applications, we offer silos that perfectly match your operations:Custom capacities tailored to feed consumption and delivery frequencyOptimized hopper angles for different feed typesCorrosion-resistant for fertilizer and other aggressive substancesConfigurable online with our agricultural configuratorWinter service: effective ice controlFor municipalities and road authorities, we deliver road salt silos and brine tanks:Fully corrosion-resistant against aggressive properties of saltMinimal bridging due to excellent insulation propertiesBrine dissolvers for environmentally friendly wet spreading techniquesMobile silos for flexible locationsEvery project is unique. That requires 50 years of experience.With more than 50 years of knowledge, a team of market specialists and craftsmen in production, we know what works. We think along, we engineer along, we install on-site, and ensure you can always move forward.Our custom approach in practice:1. Analysis of your situationProduct specifications and flow characteristicsLocation requirements and spatial limitationsProcess integration and connectionsSafety and certification requirements2. Custom engineering3D design tailored to your specificationsCalculations for strength and stabilitySelection of appropriate materials and resinsIntegration of desired options and accessories3. Production in our own factoryManufacturing in one piece up to 9 meters diameterQuality control in every production phaseCoating in desired RAL colorPre-assembly of all components4. Installation and serviceProfessional transport to your locationExpert installation by our own fittersCommissioning and handoverSupport through Service & AftersalesThe Polem agricultural configurator: custom solutions within reachFor standard agricultural applications, you can easily configure your silo yourself with our online configurator. Choose diameter, capacity, outlet, color, and accessories. Within a few clicks, you request a quote and receive tailored advice.Service that continues, even after deliveryPolem products are built for decades of use. Our service ensures they grow with your process:Polem Expert Check - periodic inspections by our fittersWall thickness and hardness measurements - preventive maintenance prevents downtimeModifications and upgrades for changing process requirementsSpare parts directly from stockWhy choose Polem custom solutions?It's not a silo or tank. It's a Polem.No project is standard. So at Polem, you don't get a standard solution either. You get a solution that fits. A solution that performs reliably for years. An investment in continuity and certainty.Our mission: delivering certaintyWe don't deliver silos or tanks. We deliver certainty. Premium storage solutions that eliminate risks and improve processes. At Polem, quality is central - in material, design, and service.Our vision: challenger in the entire industryWe want to be leading in storage solutions, not only as a frontrunner in composite, but as a challenger in the entire silo and tank industry. Through uncompromising quality and custom solutions, we create seamless, strong, and mirror-smooth products that set the standard.Discover what Polem custom solutions can mean for youDo you have a specific storage question? Our market specialists are happy to think along with you. From initial advice to installation and years of service - at Polem you're assured of a partner who understands what's truly important: the right flow for your process.Every grain, every drop. Quality in, quality out.

.png)

Ascension Day weekend at Polem!

We are taking a break from production: Thursday, May 29 and Friday, May 30, our doors are closed due to Ascension Day. Our employees are enjoying a well-deserved long weekend.But our website never stands still!Feel free to:✅ Check out our projects ✅ Fill in a contact form✅ Try out our agricultural configuratorAs of Monday, June 2, we are again full of energy ready to answer your questions and take on new projects.Until then: enjoy the days off!

.jpg)

Certainty for Verborg biorefinery in Farmsum: Premium composite silos for optimal process flow

In Farmsum, we recently installed two new composite silos as an expansion alongside existing facilities. These premium storage solutions are specifically designed for an innovative biorefinery focused on continuity, process reliability, and sustainability.Customization for specific needsThe new installation includes:A 70 m³ silo for activated carbonA larger 122 m³ silo for bleaching earthThese silos are fully tailored to the specific characteristics of activated carbon and bleaching earth, taking into account their unique flow behavior. This ensures reliable and consistent supply of raw materials in the production process.Advantages of Polem composite silos for biorefineriesThe seamless, strong, and mirror-smooth construction of our GRP (glass reinforced plastic) silos offers significant advantages:No product residues - Materials flow through smoothly thanks to the smooth inner wallLess maintenance - GRP is corrosion-resistant and requires minimal maintenanceProcess reliability - Constant flow without disruption of the production processLonger lifespan - Durable construction with a lifespan of 20-30 yearsWhy this biorefinery chose PolemFor innovative production processes such as those at this biorefinery, Verborg in Farmsum, operational reliability is essential. The client chose Polem for our uncompromising quality and specialized knowledge of flow properties of powders such as activated carbon and bleaching earth.At Polem, quality is central - in materials, design, and service. Every grain, every drop counts. This project perfectly demonstrates how our premium storage solutions contribute to optimal process flow and maximum efficiency.Look beyond standard solutionsAre you also looking for certainty in your production process? Discover how our customized composite solutions can contribute to better process flow, less maintenance, and lower operational costs. Contact one of our market specialists for more information or advice, or take a look at our other projects.Every grain, every drop. Quality in, quality out.

Composite silos and tanks ensure optimal process reliability

For those who value product quality and process reliability, storage is not a secondary matter.In a world where business continuity becomes increasingly important, reliable storage of raw materials is not a luxury but a necessity. Whether you're active in the food industry, agricultural sector, chemicals, or sustainable energy – the quality of your storage systems directly determines the quality of your end product. This is where we have distinguished ourselves for more than 50 years as specialists in premium composite silos and tanks.The unparalleled advantages of composite storage for your business processesImagine a storage system that is completely corrosion-resistant, requires minimal maintenance, and is perfectly tailored to your specific product and process. This is exactly what we deliver with our seamless composite silos and tanks.The glass-reinforced plastic (GRP) from which our products are manufactured offers significant advantages over traditional materials such as steel or concrete:Seamless - No sealant joints or welds = no weak pointsMirror-smooth - Prevents caking, promotes flowInsulating - Protects against condensation and temperature influencesCorrosion-free - Resistant to aggressive substances and weatherLow maintenance - Less downtime, lower costsThese properties make our storage systems not only more sustainable, but they also directly contribute to the efficiency and reliability of your business processes.Customized solutions for every industrial applicationWhat truly distinguishes Polem is our integrated approach. Our experts understand that each sector and each application has unique requirements. That's why we offer fully customized solutions, tailored to your specific needs. Whether it concerns storage capacities up to 1,500 m³, diameters up to 9 meters, or specific requirements for temperature, pressure, or safety - we design and build exactly what you need. Our experts collaborate with you on:Flow behavior of your productOptimal material combinationsIntegration with existing systemsSafety provisionsRegulations and complianceAfter installation, we remain involved. With our AfterSales department, you have a partner that ensures your continuity.The right solution for every sectorFood IndustryFor food processing companies, we supply FDA-approved, EU1935/2004-certified silos and tanks. These are perfect for storing:Flour and mealSugar and sweetenersStarch and binding agentsCocoa and chocolate productsVegetable oilsAnimal feedFor compound feeds and grains, residue-free emptying is important. Composite prevents segregation and maintains product quality.Feed manufacturers rely on our systems for storing:Compound feedsGrains and grain derivativesPremixes and additivesSoy productsMinerals and liquid additivesChemicalsFor the chemical sector, we develop storage systems that withstand the most challenging media:AcidsSalt solutionsReactive chemicalsSolventsProcess fluidsSustainable energyIn the biogas and sustainable energy sector, we offer solutions for:BiomassFermentation tanksDigestate storageProcess waterWinter servicesFor de-icing, we supply:Road salt silosBrine tanksSalt dissolversEngineering and project management: the complete Polem approachWhat truly distinguishes Polem is our integrated approach. For complex projects requiring extensive engineering, our experienced project managers are ready to assist you. They coordinate the entire process - from the initial design phase through to completion and aftercare.Our experts collaborate with you on:Flow behavior of your productOptimal material combinationsIntegration with existing systemsSafety provisionsRegulations and complianceAfter installation, we remain involved. With our AfterSales department, you have a partner that ensures your continuity. Regular inspection by our technicians - the Polem Expert Check - protects you against unexpected repair costs, business interruptions, and safety risks.Expert Check: measurably less downtime and lower maintenance costsDid you know that preventive maintenance is considerably more cost-effective than unplanned repairs? The Polem Expert Check is an advanced inspection service where our specialists use sophisticated measuring equipment to accurately map the condition of your storage systems.During this thorough inspection, we measure the wall thickness and material strength of your silos and tanks using special equipment. The measurements are compared to the original production values, allowing us to identify wear and potential damage early. You receive a detailed report with all findings, including photos, measurements, and concrete recommendations.Benefits of Expert Check:Less unplanned downtimeLower maintenance costsLonger lifespanOur customers confirm that regular Expert Checks are an excellent investment that quickly pays for itself. Instead of reacting to problems, you can proactively plan your maintenance at times that least disrupt your business operations.Premium stands for uncompromising quality and process reliabilityPremium sounds like a buzzword, but at Polem it means we make no compromises when it comes to quality. When we walk through our production facility, we feel that employees have paid attention to detail. Each of our products not only meets general standards but also our own standards. That bar is set just a bit higher.Every material used to make silos and tanks has its advantages and disadvantages. We choose composite with full conviction. Together with our methodology, we create storage products that are unparalleled: seamless, strong, and mirror-smooth.Start improving your storage processes todayWould you like to know more about the possibilities of composite silos and tanks for your specific application? Our market specialists are happy to consult with you about the best fitting storage solution for your company.It's not just a silo or tank. It's a Polem.Take action now: Would you like to know more about the possibilities of composite silos and tanks for your specific application? Our market specialists are happy to consult with you about the best fitting storage solution for your company.✅ Schedule a no-obligation consultation✅ Or start directly in our ConfiguratorEvery grain, every drop. Quality in, quality out.

Optimal storage solutions for complex liquids and moisture-sensitive materials

Every grain, every drop. Quality in, quality out.When it comes to storing complex liquids or moisture-sensitive solid materials, every detail matters. Polem eliminates risks. No compromises in quality.At Polem, we set the bar higher than standard. Premium means that each silo and tank meets our own strict standards, not just the general requirements. For more than 50 years, Polem has been delivering high-quality, seamless storage solutions that work. Always.The challenges of complex storageWith sensitive products, it's all about control. Without the right storage construction, you'll face:Condensation due to temperature fluctuationsClumping or separation of productsMoisture absorption and quality lossDifficult discharge or blockagesThese problems lead to downtime, waste, and frustration. Polem prevents this.Why composite?A Polem silo or tank is seamless, strong, and mirror-smooth – made from high-quality GRP composite. There are good reasons we deliberately choose this material:Corrosion-resistant – even with aggressive or moist contentsInsulating – prevents condensation and temperature peaksLow maintenance – no coating or periodic painting requiredHygienic – easy to clean, suitable for food, feed, and chemicalsFor high-viscosity liquidsSome liquids solidify or become too thick at low temperatures. Think of molasses, fats, or glycerin. Polem offers various solutions:Hot water circuit – for uniform heating via spiral tubesElectric tracing – heats the bottom of the silo or tankImmersion heaters – direct heating inside the tank, with temperature zone controlFor moisture-sensitive solidsProducts such as sugar, salt, or starch quickly attract moisture. With an air dryer, you can prevent this:Connected to the filling pipeDry air prevents condensation in pipes and siloProduct and dust filter remain dry and clean100% custom-made – AlwaysEach Polem silo or tank is tailored to its application. Our capabilities:✅ Capacity up to 1,500 m³✅ Diameter up to 9 meters✅ Available in any RAL color✅ With platforms, cage ladders, or leak detectionFocus on your processYour production process is central. Polem ensures the right flow: reliable storage that supports your process rather than disrupting it. Our storage solutions are part of your success for tomorrow.Expert Check – long-term securityQuality means longevity. It's that simple. That's why we offer the Polem Expert Check: a periodic maintenance program carried out by our service technicians.Measurements of wall thickness and hardnessVisual inspection of interior and exteriorAdvice and possible execution of repairsUp to 7 years longer lifespan for your installationInvesting in continuityA Polem silo or tank is built to last at least 20 years. The advantages:✅ Lower total cost of ownership✅ Reliable protection of your valuable products✅ Less downtime, more efficiencyYour situation, our solutionDo you have specific requirements for your storage solution? Our market specialists are here to help. Contact us directly.It's not a silo. It's not a tank. It's a Polem.

Custom storage solutions: how Polem has excelled in composite silos and tanks for over 50 years

Every grain, every drop. Quality in, quality out.Since 1972, Polem has been developing high-quality composite silos and tanks. For companies in the food industry, agricultural sector, chemical industry, or infrastructure, proper storage is crucial. Our seamless, strong, and mirror-smooth silos ensure maximum product quality, minimal downtime, and low maintenance costs.Why composite is the future of storageComposite is the material of choice for modern storage. It's corrosion-resistant, low-maintenance, and provides excellent insulation against temperature and moisture fluctuations. Unlike steel or aluminum, composite doesn't suffer from rust, condensation, or high maintenance costs.Polem silos and tanks are:Seamless and food-safe (compliant with EC 1935/2004 and EU 10/2011)Lightweight and quick to installResistant to chemicals, moisture, and extreme temperaturesOptionally insulated with a thermal-bridge-free sandwich constructionOur unique SEAMLESS technology guarantees a completely seamless construction for optimal hygiene and safety.It's not a silo. It's not a tank. It's a Polem.Custom solutions for every industryOur silos and tanks range from 4 m³ to an impressive 1,500 m³. This allows us to serve a wide range of sectors:Food & animal feedIn the food industry, everything revolves around hygiene. The smooth interior walls of our tanks prevent product accumulation and bacterial growth. Ideal for applications such as sauce fermentation or storage of sugars and grains.Agricultural sectorFor livestock farmers, quality feed is essential. Composite silos protect the contents against temperature fluctuations, preserving nutritional value. Thanks to a smart funnel design, separation of mixed materials is prevented.Chemical & industrialComposite is resistant to corrosive and sensitive substances. From acids to salts – our silos comply with ATEX standards and withstand chemical exposure.Road salt & infrastructureOur salt and brine silos are developed for maximum durability under harsh conditions. Prevent blockages, minimize moisture development, and ensure reliable de-icing operations.Project guidance from design to installationWhat makes Polem unique is our complete project guidance. From the first conversation through to the final installation, our specialists guide every detail. We think along in layout, process integration, safety, and maintenance. Thanks to our years of experience in diverse markets, we know exactly what to pay attention to. Not a standard solution, but a smart, customized storage solution. Our approach is secured through our ISO 9001 certificate, with which we structurally work on quality, safety, and reliability in design, production, and service.We don't deliver a silo or tank. We deliver certainty.More than just a product: A complete solutionAt Polem, we don't just deliver a silo. We deliver a reliable solution. We think alongside you from initial design through maintenance and inspection:Engineering: Our experts calculate every detail.Innovation: Such as the weighing support for silos Ø2800–Ø3500 mm, for faster installation and better performance.Safety: Stainless steel grounding systems, explosion panels, and ATEX-compliant designs.Inspection & maintenance: With a periodic Polem Expert Check, you prevent downtime and extend the lifespan by an average of 7 years.Care for your raw materials. To the core.Customer-focused and future-proofOur silos and tanks are designed for decades of performance. We aim for long-term cooperation and actively collaborate with system integrators and dealers. Our service doesn't stop at delivery – we remain involved."With a Polem silo, you're not buying for one day, but for thirty years of reliable storage."Ready for your storage challenge?Whether you're active in agribusiness, chemicals, or food – we offer a solution that fits. From a single silo to a complete silo park. Reliable. Sustainable. Seamlessly integrated into your process.Our experts are ready to develop the perfect solution with you. Whether it's a single silo for a small-scale agricultural business or a complete silo park for industrial applications – we have the knowledge, experience, and products to meet your requirements.Design your own agricultural silo or tank with our configurator and receive immediate tailored advice. Start ConfiguringContact us today and discover how we can transform your storage challenges into opportunities for efficiency and quality improvement. Because as our slogan states: "Every grain, every drop. Quality in, quality out."It's not just storage. It's a Polem.