Composite silos eliminate production stops at Raiffeisenagrar

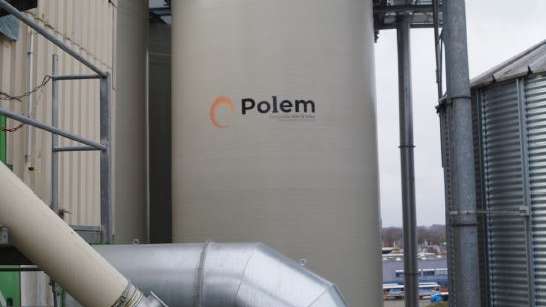

From blockage to breakthrough: how Raiffeisenagrar achieved cleaner, faster, and more cost-effective feed production with Polem composite silos

In the heart of Lower Saxony, in the German town of Ankum, lies a modern animal feed production facility run by Raiffeisenagrar. When the company decided to modernize the factory in 2023, one bottleneck stood out: the storage of difficult-to-flow raw materials. This challenge required more than just new silos, it called for a structural solution.

Challenges and analysis

The existing steel silos caused significant problems:

- Products like rapeseed and soybean meal stuck to the walls

- There was product segregation, affecting feed consistency

- Condensation led to hygiene risks and extra cleaning

- Manual hammering was often needed to release stuck materials

For a company committed to quality and continuity, these issues were unacceptable. The need to improve efficiency while meeting strict hygiene standards made a fundamental shift necessary.

Solution and implementation

Raiffeisenagrar deliberately chose to switch to Polem composite silos, building on a previous positive experience with a composite tank. The implementation involved close collaboration, with Polem providing tailored advice and 3D designs for seamless integration.

A total of eight composite silos with a 30-degree discharge angle were installed. They were fully operational within 1.5 days, thanks to flawless coordination between both parties.

Even difficult-to-flow raw materials like rapeseed and soybean meal discharge easily from these silos. They stay clean and are a pleasure to work with, said Thorsten Kühl, operations manager.

Results

The impact was immediate and measurable:

- Smooth discharge even with meal-based products like choco meal

- No more hammering—products release effortlessly

- Consistent, controlled first-in-first-out material flow

Condensation is virtually eliminated, avoiding costly building additions

The silos remain structurally clean, reducing cleaning time and costs

The combination of top quality, expert support, and competitive pricing makes us recommend Polem without hesitation.

Lessons learned

This project showed that something as ‘simple’ as a silo can have a huge impact on the entire production chain.

- Technology works best when it thinks along with you: collaboration was key

- Investing in quality pays off: in time, hygiene, and maintenance

- Hygiene isn’t a side issue: it's the foundation of modern feed production

Conclusion

Raiffeisenagrar didn’t just choose a new storage solution, they chose a future-ready transformation of their feed production. Thanks to Polem’s composite silos, the factory is now faster, cleaner, and more efficient. And just as importantly: the work environment for staff has improved.

The partnership with Polem continues to stand as an example of technical expertise, customer-focused thinking, and long-term quality.

FAQ

- Why did Raiffeisenagrar choose composite silos specifically?

Composite offers excellent hygienic properties, resists condensation, and ensures better material flow. Combined with previous experience with Polem, this gave full confidence to switch completely. - How quickly were the new silos installed?

Installation took just one and a half days. Thanks to good planning and Polem’s support, the process went smoothly with no disruption to production. - Which materials caused the most issues before the switch?

Rapeseed and soybean meal were the main culprits. Even products with a meal component, like choco meal, are now discharged without any issues. - Were there any cost savings?

Yes, in multiple areas. Reduced cleaning time and the fact that no additional building was needed due to the lack of condensation led to significant savings. - How is Polem's support after installation?

Polem remains actively involved even after delivery. Their ongoing technical support builds confidence and adds long-term value.

Contact us

Curious how Polem can improve your production process too? Please contact us.

Our services

Installation

Your new silo or tank, carefully assembled and installed.

Inspections

One-time or periodic inspections of our silos and tanks. For control, safety and maintaining your proper flow.

Service

For repair, replacement, spare parts and advice. Meet our service team.

Repairs

In most cases, we repair damage to original quality.

Advice

Our market specialists assist you with industry-specific advice.