Sustainability

We integrate sustainability at every step within our development and production process.

Our program

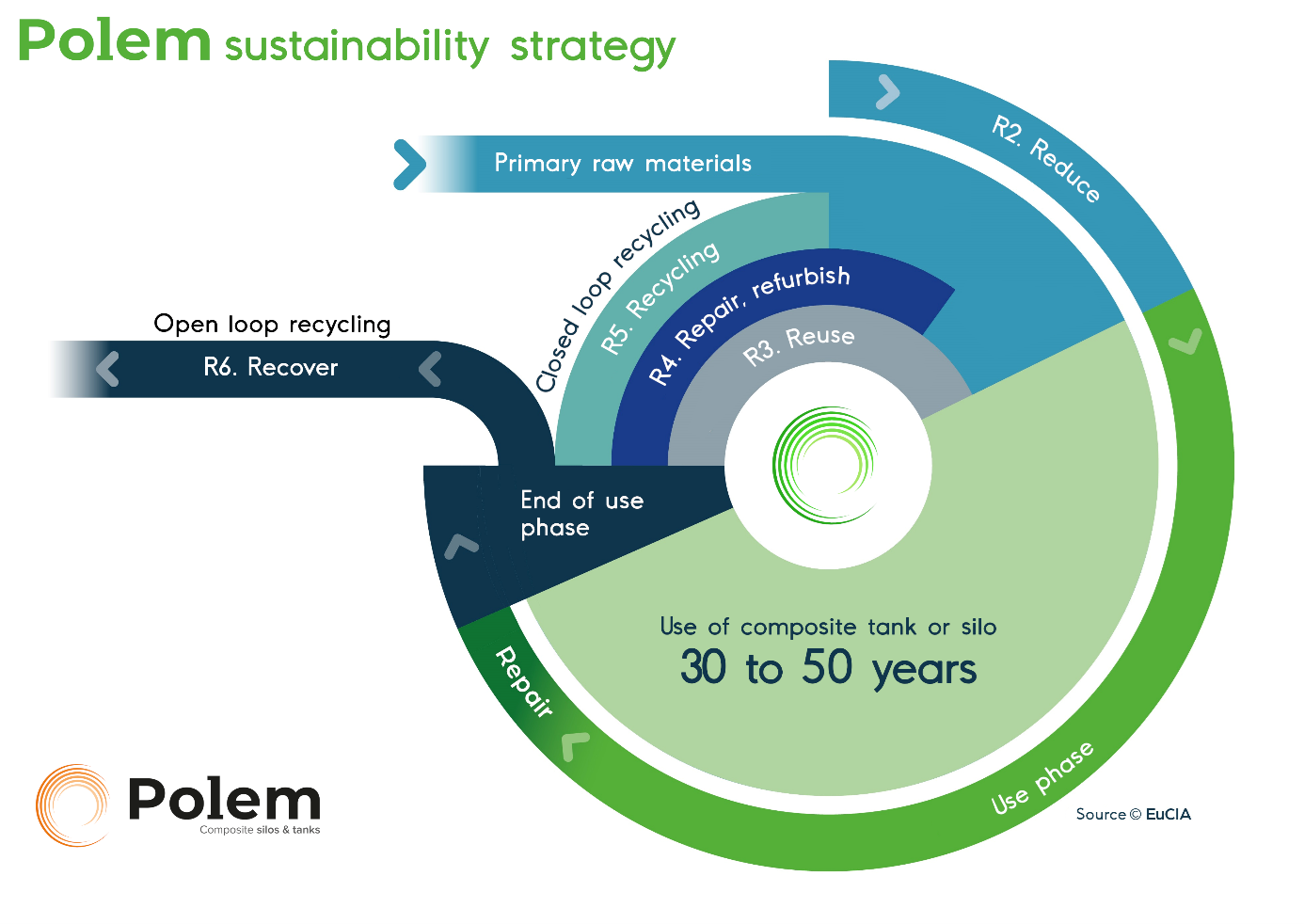

Polem silos & tanks last a long time. Sometimes up to 30 to 50 years. They help prevent waste and allow cuts in maintenance and energy costs. All sustainable features. But we want to move toward making the chain circular. For this we use the R-ladder of circularity.

R1 Refuse and rethink

We minimize logistics actions to the greatest extent possible

While goods were previously stored piece by piece, it is now possible to switch to bulk storage in Polem silos and tanks. This transition has not only led to a significant reduction in logistics operations, but also contributes to reducing CO2 emissions by half.

R2 Reduce

We strive to use as few raw materials as possible

Minimizing raw material consumption is a core principle for us. We carefully consider the origin of our materials and aim to avoid unnecessary use. Compared to alternatives, our composite silos and tanks require up to 50% fewer raw materials for production. This not only leads to significant savings but also reduces the ecological footprint of the manufacturing process. Additionally, the long lifespan of our composite silos and tanks further reduces raw material consumption. The low-maintenance nature of composite also contributes to lower maintenance needs, less downtime, and a reduced environmental impact.

R3 Reuse

We give silos and tanks a second and third life

When a silo or tank is no longer needed for its original purpose but can be repurposed, our technicians modify it on-site while preserving its original characteristics.

If the production process changes, or if the silo or tank is no longer required for any other reason, our Service Team can dismantle and relocate it. Depending on the needs of the new process, we can even modify it before installation.

R4 Repair/refurbish

We repair damage

During inspections, we thoroughly assess the structure for any defects. When necessary, we develop a repair plan. In most cases, we are able to fix the damage while preserving the original quality of the structure.

R5 Recycle

Recycling in the right way

If a second or third life is not possible, or if something cannot be repaired, we turn to recycling.

- Mechanical

This process involves reprocessing composite materials so they can be reused in composite structures, either as core or filler material.

- Pyrolysis

In pyrolysis, materials are heated without oxygen, causing them to break down into gases, liquids, and solids. These products can then be processed further to produce valuable chemicals and energy.

- Chemical Recycling

This method breaks composite materials into their components, with depolymerization being a common technique.

The options for recycling composite materials are continually expanding. Some key examples include:

- Composite Recycling

- Roth - International

- Recycling end-of-life composite parts

- Smart Circular

- Extreme Eco Solutions

- Circular Recycling Company

R6 Recover

Energy recovery

This step is only pursued when previous options are not feasible. By burning materials in a controlled environment, heat and/or energy is produced. Naturally, we aim to avoid this step whenever possible.

What does Polem do for sustainability?

- Processing its own composite residuals into new products

- Reducing raw material and energy consumption through automation in production

- Researching alternative raw materials

More information?

Do you have specific questions about our sustainability efforts? Please don’t hesitate to contact us.