In industrial environments where powders and liquids are stored, safety is paramount. Explosive substances such as flour, sugar, starch, and chemical powders require specialized storage solutions that meet the strictest safety standards. Polem develops composite silos that not only provide optimal protection but also ensure long service life and minimal downtime.

Why explosion safety is crucial in bulk storage

When storing dust explosion-hazardous products, one of the greatest risks is the domino effect. This occurs when an initial explosion triggers a chain of subsequent explosions. While the first explosion is often not catastrophic, the third or subsequent explosions usually cause the greatest damage.

In silo parks, where silos are often interconnected through combined filling systems, ventilation systems, extraction installations, or filter systems, dust explosions can spread at lightning speed. This emphasizes the importance of adequate preventive measures in the design of storage systems.

Explosion safety according to ATEX guidelines

It is the responsibility of the client to determine whether the product stored in a silo is dust explosion-hazardous. The client must determine whether the silo should be equipped with explosion panels or other protective measures.

Strict European ATEX guidelines apply to explosive environments. ATEX zones are defined as follows: zones 20, 21, and 22 for dust explosion hazards and zones 0, 1, and 2 for gas explosion hazards. Polem's composite silos are specifically designed to comply with these ATEX requirements.

Composite: the ideal material for explosion-safe storage

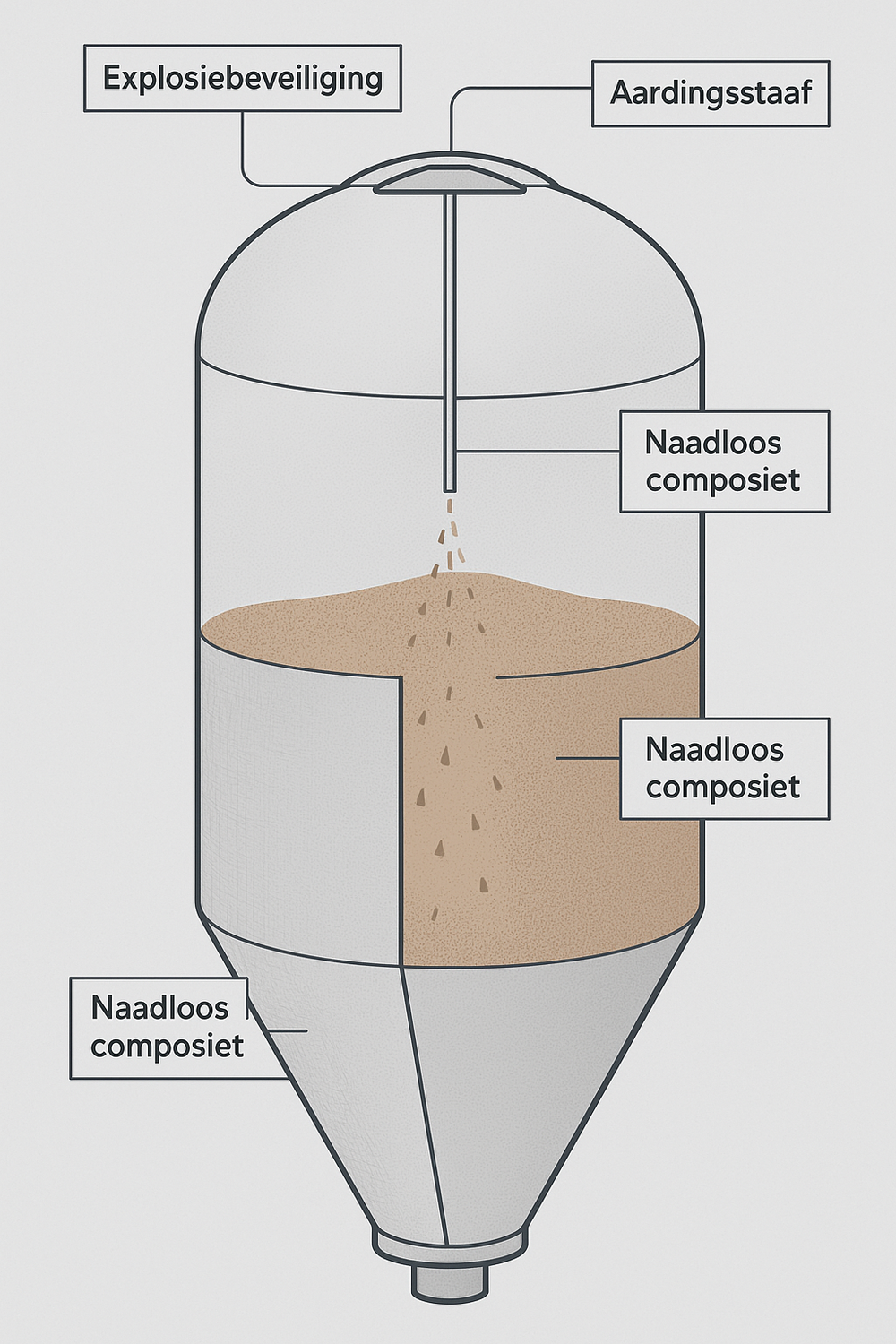

Seamless construction prevents risk points

A Polem silo or tank is seamless, strong, and mirror-smooth thanks to powerful composite materials. Immune to corrosion, protective against moisture, and easier to maintain than traditional materials. This seamless construction is crucial for explosion safety because there are no welds or connections where dust can accumulate and ignition sources can occur.

Superior roof construction for safe pressure relief

Polem produces silo roofs as standard in a domed shape (Klöpperbodem). This roof shape offers important advantages over the "Chinese hat" shape often used with metal silos. Due to the domed shape, Polem silo roofs can be designed for a P-red of 1.0 bar. This is essential for silos storing dust explosion-hazardous products and equipped with explosion panels.

Metal silos can typically only handle a P-red ≤ 0.5 bar. A higher P-red means less relief surface area needed for explosion panels. With Polem silos, this can usually be realized entirely in the roof, while with metal silos, the silo wall often needs to be utilized as well.

Integrated explosion protection

Explosion panels: safe pressure relief

Explosion panels are essential safety devices that ensure that in the event of a dust explosion in a silo, the explosion pressure is discharged in a controlled and safe manner. This prevents major damage to the silo and surroundings, as well as possible fire or serious personal injury.

The flanges for explosion panels are always laminated flush with the inside of the roof, so that in the event of a dust explosion, the built-up pressure can escape quickly and with minimal resistance through the explosion panels.

Rupture detectors and maintenance

Explosion panels are usually equipped with rupture detectors. These give a signal when a panel has opened. The panel and rupture detector must be replaced immediately in that case, because an open connection to the outside air can cause dust dispersion, moisture, rain, and other contamination in the silo.

Innovative grounding system for electrostatic safety

Certified safety

Polem's grounding installation was developed in cooperation with ISMA (Kontich, Belgium), a recognized authority in the field of grounding systems. ISMA has certified Polem composite silos with grounding installation as suitable for storing products that pose dust explosion hazards.

Advanced technical specifications

The current generation of grounding rods is made of special stainless steel spring steel, which offers significant advantages: one-piece construction without weld connections, eliminating the risk of breakage and damage from loose parts in the silo or transport systems, reduced forces due to the smaller surface area of the new grounding rods, and flexible suspension where the grounding rods hang freely on the inside of the roof and follow the flow pattern of the product in the silo.

Polem's new grounding system offers maximum safety for explosive bulk materials, a hygienic design without product accumulation with flat stainless steel screw plug and open fork connection, reliable and robust construction of high-quality materials, and easy inspection and maintenance thanks to the flexible design.

Long-term benefits of composite in explosion-safe applications

Durability and ease of maintenance

We deliberately choose glass fiber reinforced plastic (GRP). It is lightweight, strong, corrosion-resistant, and low-maintenance. This allows us to build silos and tanks that last longer, cause less downtime, and meet requirements for food safety, ATEX, and sustainability.

Minimal maintenance costs

Our silos and tanks are seamlessly produced, strong, and mirror-smooth. Every product with us meets not only general standards but also our own standards. That bar is set just a little higher. This quality standard translates directly into lower maintenance costs and more reliable operation throughout the entire service life.

Custom solutions for optimal safety

Our products are seamlessly produced, strong, and tailored to the customer's process. No standard solutions, but custom work: focused on application, location, and sector. Every Polem silo is fully custom-designed, taking into account the specific properties of the stored product, process conditions, and applicable safety standards.

Conclusion: investing in safety and continuity

Explosion-safe bulk storage requires more than just compliance with regulations – it requires an integrated approach where safety, sustainability, and operational security come together. Premium means uncompromising quality for us. In our production hall, you can see the craftsmanship. The attention to every detail makes the difference for customers.

Polem's composite silos with integrated explosion protection and innovative grounding systems not only provide maximum safety but also ensure low maintenance costs, long service life, and minimal downtime.

It's not a silo or tank. It's a Polem.

Every grain, every drop. Quality in, quality out.

Would you like to increase the safety of your bulk storage while investing in sustainability and operational security? Contact our specialists for a no-obligation consultation about explosion-safe storage solutions that perfectly match your specific needs.